|

|

#16

|

|||

|

|||

|

Quote:

Quote:

|

|

#17

|

|||

|

|||

|

Quote:

A compensated nut is nothing like a compensated saddle, which effects both open and closed strings at any fret. __________________________________________________ __________ Quote: Q - Why not a zero fret? A - A zero fret is no different from a properly made nut, where the bottoms of the string slots are level with the fret plane. In that case, wouldn't each fret have to be intonated, since playing an open string would be the same as playing a string running off a fret? Quote: Q - or lower the action at the nut? A - See above. The correct nut height is the same as the frets. That does not negate the reason for this compensation. When fretting close to the nut, the string is bent at a sharper angle, which increases the tension. If a string running off the nut has the same action as a string running off a fret, why would the string be bent at "a sharper angle" close to the nut?

__________________

Jim _____________________ -1962 Martin D-21 -1950 Gibson LG1 -1958 Goya M-26 -Various banjos, mandolins, dulcimers, ukuleles, Autoharps, mouth harps. . . |

|

#18

|

|||

|

|||

|

>> If a string running off the nut has the same action as a string running off a fret, why would the string be bent at "a sharper angle" close to the nut?

It's basic trigonometry. The strings do not lie in the fret plane.

__________________

Martin D-18 (1964) Martin D-28 (1971) Ibanez 2470NT (1977) Gibson ES-175 (1981) Gibson ES-165 (1992) Yamaha AEX-1500 (1996) D'Angelico EXL-1DP (2005) Peerless New York (2007) Epiphone Elitist Byrdland (2008) |

|

#19

|

||||

|

||||

|

Quote:

. Cheers! . Cheers!

__________________

”Lorem ipsum dolor sit amet” |

|

#20

|

|||

|

|||

|

Quote:

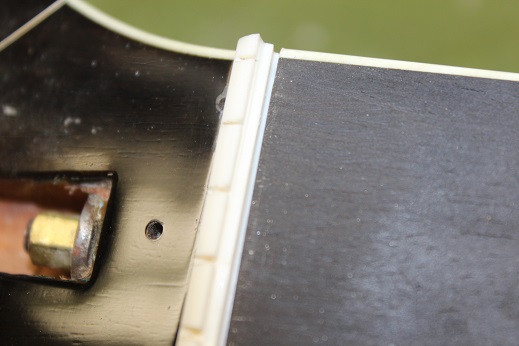

So typically we start with a broken nut, so the nut needs to be replaced. Once the nut has been replaced we need to file the front edge of the nut away so it is flush with the fretboard without damaging the fretboard, then a shelf needs to be filed into the front face of that nut for the frets tang area, basically a fret needs to fit into a gap that currently does not exist, then clean and tidy, it easily doubles ones time Steve

__________________

Cole Clark Fat Lady Gretsch Electromatic Martin CEO7 Maton Messiah Taylor 814CE Last edited by mirwa; 09-27-2018 at 07:59 PM. |

|

#21

|

|||

|

|||

|

Quote:

I do understand that replacing a nut with a zero fret would be a more difficult job.

__________________

Jim _____________________ -1962 Martin D-21 -1950 Gibson LG1 -1958 Goya M-26 -Various banjos, mandolins, dulcimers, ukuleles, Autoharps, mouth harps. . . |