|

|

#46

|

|||

|

|||

|

Quote:

I walked someone else through the process of correcting the same thing done with a Fishman jack a couple of states away from me. When the problem was described I stopped him after the first sentence and told him what was wrong. It's such a common malady with end pin jacks that I'm surprised that the need for the barrel to be positioned correctly isn't stated in large bold type in the installation instructions. That might help to prevent a lot of problems that give end pin jacks a bad name. |

|

#48

|

||||

|

||||

|

This for me as well. If there's no end-pin hole then that's what a tapered reamer is for. If there already is an end-pin hole, you already have a pilot hole and only need to enlarge it. The jack is not tapered so no taper is needed. Simple drill bit is all that's necessary but I would make sure it's new or sharp.

|

|

#49

|

|||

|

|||

|

Quote:

If there is no endpin hole then you create one using a drill, not a reamer. Once the hole has been created, then you can use the reamer. |

|

#50

|

|||

|

|||

|

For creating a hole in a guitar, be it for an endpin, machine head etc, a reamer is IMO best, be it a tapered reamer, stepped reamer or what have you.

Drills themselves are kind of inappropriate for fine wood work, the clearance angle and angle of twist make for a hole that typically displays tear out, tear out is bad enough in a guitar being built, its even worse in a guitar that has been finished Steve

__________________

Cole Clark Fat Lady Gretsch Electromatic Martin CEO7 Maton Messiah Taylor 814CE |

|

#51

|

|||

|

|||

|

Quote:

Certainly, creating an undersized hole using a drill followed by the use of a reamer will produce a straight, smooth-walled, accurately sized hole. However, I'd suggest that there really don't need to be close tolerances on the fit between an endpin jack and the hole in the end of a guitar. Consequently, a drill can well be used to create the hole to sufficient tolerance. Any drill bit configuration and technique that produces a clean, no-tear-out hole is sufficient. Finishing the hole with a reamer is certainly an option. |

|

#52

|

|||

|

|||

|

All good, i actually was not addressing his comment.

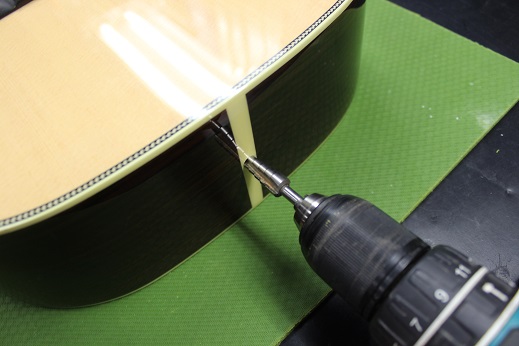

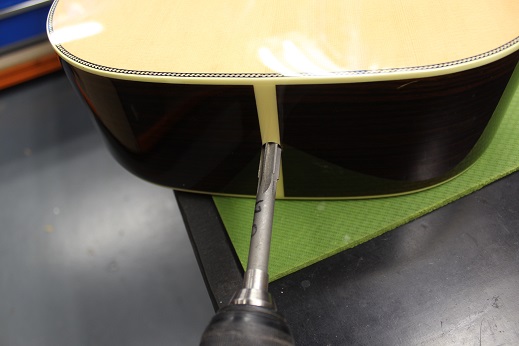

I find any hole started with a drill bit has tear out, in a perfect world its exactly as per your reply, the tear out is small enough to be encompassed by a washer or removed by subsequent reaming. I use a step drill when i do it, heres a hole being drilled into the side of a uke with a stepped reamer, so very fragile and splits real easy   Endpin situation  If the step reamer is not quite the perfect size,i follow up with a machine reamer, i use these as i have every size from 1-15mm in .1mm increments

__________________

Cole Clark Fat Lady Gretsch Electromatic Martin CEO7 Maton Messiah Taylor 814CE Last edited by mirwa; 05-02-2019 at 06:33 AM. |

|

#53

|

|||

|

|||

|

Quote:

I have found the thread quite interesting ... I see that nobody uses the method which I have developed and use all the time , and which IMHO is the best. I do realize of course that everybody thinks their own method is the best ... I will be fitting a K&K next week, and will attempt to take some pictures to explain my approach. |

|

#54

|

|||

|

|||

|

It's a ten year old thread too!

Step drills work just fine but as mentioned the jacks are a hair smaller then 1/2in. You could use heat shrink tubing or something to thicken the jack up but if players wear straps, and who doesn't on stage' that's a lot of wiggle back and forth which can cause problems. The reamer is clearly the best tool. I use it after step drilling up. |

|

#55

|

||||

|

||||

|

Quote:

Mine are all done that size, the oldest one has had the jack in there for 17 years, never had any problem with any of them. The usual disclaimers apply......IMHO, YMMV etc.

__________________

John Brook ‘Lamorna’ OM (European Spruce/EIR) (2019) Lowden F-23 (Red Cedar/Claro Walnut) (2017) Martin D-18 (2012) Martin HD-28V (2010) Fender Standard Strat (2017-MIM) |

|

#56

|

|||

|

|||

|

Quote:

Absolutely right, John If I can be nitpickingly pedantic for a moment, I would just point out that 15/32" is indeed the nearest imperial size, but technically the correct size hole is 12mm. These jack sockets are manufactured to metric standards rather than to imperial standards, but the difference between 15/32" and 12 mm is so small as to be insignificant in practical terms. |

|

#57

|

||||

|

||||

|

Quote:

__________________

John Brook ‘Lamorna’ OM (European Spruce/EIR) (2019) Lowden F-23 (Red Cedar/Claro Walnut) (2017) Martin D-18 (2012) Martin HD-28V (2010) Fender Standard Strat (2017-MIM) |

|

#58

|

|||

|

|||

|

Quote:

Ovenight, IMHO , the British currency just seemed to lose all value ... shopkeepers hiked prices up to unprecedented levels which would have sparked a revolution in the pre-decimal era. But the public , in toto, unfortunately did not have the nous to see what had been foisted upon them. Apologies for semi-political thread drift ... now back to your scheduled program. |

|

#59

|

||||

|

||||

__________________

John Brook ‘Lamorna’ OM (European Spruce/EIR) (2019) Lowden F-23 (Red Cedar/Claro Walnut) (2017) Martin D-18 (2012) Martin HD-28V (2010) Fender Standard Strat (2017-MIM) |

|

#60

|

|||

|

|||

|

Quote:

|