|

|

#31

|

|||

|

|||

|

Quote:

__________________

http://victoryguitarshop.com/ |

|

#32

|

|||

|

|||

|

The guns I have are HVLP, I have been wanting to get an AM-8008/5008 “SmartPak” combo. Since these are LVLP they may be just what I need.

https://homesteadfinishingproducts.c...guitar-making/

__________________

http://victoryguitarshop.com/ Last edited by Victory Pete; 04-26-2021 at 07:32 AM. |

|

#33

|

|||

|

|||

|

Just ordered the AM-8008/5008 “SmartPak” combo.

__________________

http://victoryguitarshop.com/ |

|

#34

|

|||

|

|||

|

Quote:

__________________

http://victoryguitarshop.com/ |

|

#35

|

|||

|

|||

|

I now have 8 oz of shellac flakes down. It is fairly thick. I have a method of determining thickness by using a flashlight, you can see a halo of light and get an idea of how thick it is. The low shiny spots are getting smaller and I will be switching to a softer foam block to do final level sanding when this is dry. My new guns are coming tomorrow so I want to be able to put down the final finish coats with them in a couple days.

__________________

http://victoryguitarshop.com/ Last edited by Victory Pete; 04-27-2021 at 12:15 PM. |

|

#36

|

|||

|

|||

|

I get fidgety in between coats of shellac, this venture turned out great. I get way more CFMs for less RPMs. Just clears window when closed.

__________________

http://victoryguitarshop.com/ |

|

#37

|

|||

|

|||

|

Can you explain how that works?

|

|

#38

|

|||

|

|||

|

If you place a small flashlight like that one on an unfinished guitar surface you will see no light. When there is a bit of finish on the guitar the finish material, if transparent, will illuminate a ring of light. The thicker the finish the more light you will see. I do have to estimate the thickness as I have no way of knowing its actual thickness in a measurable amount.

__________________

http://victoryguitarshop.com/ |

|

#39

|

|||

|

|||

|

Quote:

If I understand you correctly then, all you know is that there's a thickness but you have no idea what that thickness is. I don't see how that is helpful. |

|

#40

|

|||

|

|||

|

I have an idea if it is an appropriate thickness.

__________________

http://victoryguitarshop.com/ |

|

#41

|

|||

|

|||

|

Quote:

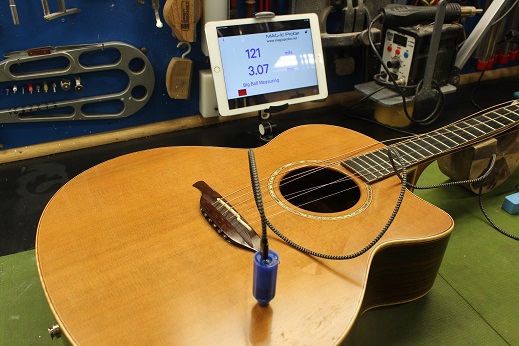

Personally, if I need to measure material thickness then I use the magi probe setup, cannot speak highly enough of the product.

__________________

Cole Clark Fat Lady Gretsch Electromatic Martin CEO7 Maton Messiah Taylor 814CE Last edited by mirwa; 04-28-2021 at 10:57 PM. |

|

#42

|

|||

|

|||

|

Quote:

__________________

http://victoryguitarshop.com/ |

|

#43

|

|||

|

|||

|

Just been looking on your website Pete, love your removable go bar press, real meaty threaded bars on there. I did similar but I got so annoyed with constantly winding 8 nuts up and down that I drilled holes and used split pins instead.

On measuring lacquer thickness I might just try your method. Previous I’ve just sprayed a 6” square blank at the same time as the work of I needed reassurance. |

|

#44

|

|||

|

|||

|

Quote:

__________________

http://victoryguitarshop.com/ Last edited by Victory Pete; 04-30-2021 at 07:50 AM. |

|

#45

|

|||

|

|||

|

I am spraying with the new LVLP QualSpray guns. They spray nice at 29 PSI. I got ahead of myself spraying the back and got a wide run, the whole width of the guitar. I am used to spraying on my flat dolly and was going to again for the final coat but wanted to see how this would go. As things usually go around here I improvised a workaround. A plastic coat hanger hanging from the lights. I think this will be part of my technique, Spay & Hang.

__________________

http://victoryguitarshop.com/ |