|

|

#76

|

||||

|

||||

|

Quote:

Quote:

Quote:

Quote:

|

|

#77

|

|||

|

|||

|

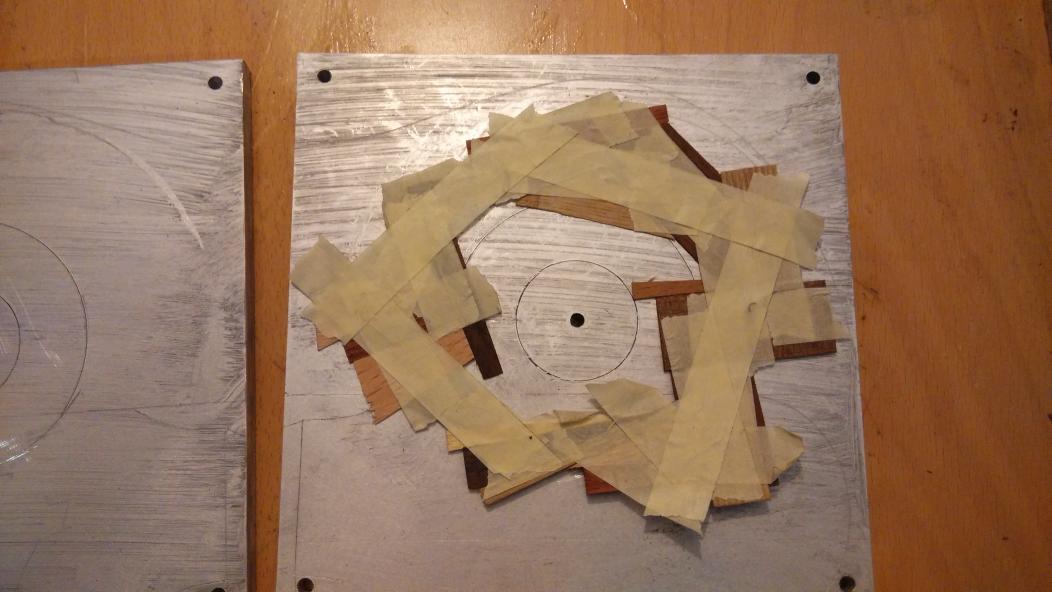

Made 2 more rosettes.

I put paper tape upside down (sticky side up), and tape it down at the edge. Then i place the pieces on. The other rosettes i made had 2 backings of veneer (crossed), but i don`t want to waste so much veneer, so i will try to put fiberglass or carbon as a backing on these two.

__________________

build, learn, grow Last edited by littlesmith; 04-25-2015 at 04:15 AM. |

|

#78

|

|||

|

|||

Neck remains the same under load  It has strings JEEH! woohoo.  Here is a sample, i can`t really play, i play bass, and even that was years ago. I went towards the building side, you can not have 2 disciplines as a calling. I am playing along with a youtube backingtrack, and recording it with a phone. Anyway here it is (and again....not a guitar player ^_^). https://www.youtube.com/watch?v=P3BR4Qzjlz0 It still needs to be sanded, so the orangepeel is gone, and then buffed, and tweak the nut and saddle of the bridge (as low as possible without buzz). When this guitar is really 100% finished i will try to get a good player and record it with a real mic (and movie). The instrument was a proof of concept and that is a success. The goal was to find out how the strength, sustain and clarity of carbon fiber can be married with the lovely warmth of cedarwood, and another goal was to break free from the Loosetop model failure, and regroup and rebuild. I am pleased with the result for this stage in development. The next will have a few structural improvements, and it will be geared towards streamlining and estetics. The next will look clean. This guitar has a classical width neck, but the real hybrid model will have a narrower neck to bring it closer to a contemporary guitar and enhance playing comfort. If this guitar was properly sanded and buffed and finetuned, i would be comfortable at a 1000 Euro valuation (1 087.5 U.S. dollars). I will try to avoid selling this for sentimental reasons. I will build this into a real company so it will be nice to still have this in years to come. I`m gonna start using electric guitar bridges on it. Very unconventional but you just can`t beat the tweakability of it. Once i have a real sustainable company i will start experimenting with pre preg carbon fiber, which is the most expensive and most high quality carbon fiber available. That would be an elite model in the range of 7500 euro. This is used in high performance racecars, airplanes, etc. Is this really necessary? Who knows, but i am on a quest to find the ultimate sound and guitar. It would not replace the normal model at 2300, but its just to push the boundries. Custom comissioned Tungstong carbide fretwire, aerospace unibody, titanium bridge. Just for fun. Hehe. The basic model will keep the business economical so it can survive, and the rest is R&D.

__________________

build, learn, grow Last edited by littlesmith; 04-28-2015 at 01:38 PM. |

|

#79

|

|||

|

|||

|

Made a soundport, it projects sound to the left ear. Not my idea, i saw it on youtube i think, but the guy had it just above the neck.

I have chosen an angle from the soundhole centerline, a line directly to the left ear.     I made a recording with a mic (still didn`t become a better guitarplayer compared to yesterday ^_^). Recorded with samson g track mic, video with phone : https://www.youtube.com/watch?v=NYxB...ature=youtu.be

__________________

build, learn, grow |

|

#80

|

|||

|

|||

|

Rosette upgrade, aluminium plates (20x20x1CM).

All the shapes are scratched in, using the new master templates as a guide. Sanded with seed oil and fine grit. The lines make sure i know exactly what comes where, and how it will be visible. The piece that would normally go under the fingerboard will be cutoff, and will always go on the headstock for unity and consistency.  Waxed so the epoxy won`t stick :  I put the pieces on and tape them from behind, this time.  Then i flip it.  Making 2 at once   I don`t have pictures from making the epoxy and backing the wood with fiberglass. I didn`t want to damage my phone. Put small bolts and nuts on  Wait 24 hrs and then post cure in an air oven.

__________________

build, learn, grow |

|

#81

|

|||

|

|||

|

Hybrid prototype 2 body (narrower neck for steelstring) :

Recess for thin bracings :  Guiling the bracing :  Glueing the headplate :

__________________

build, learn, grow |

|

#82

|

|||

|

|||

__________________

build, learn, grow |

|

#83

|

|||

|

|||

__________________

build, learn, grow |

|

#84

|

||||

|

||||

|

...there's only one guitar in the world with tungsten carbide frets, and that took an investment of $10,000 in tooling to achieve. The guitar itself is a limited-run electric that costs $51,000...

__________________

Wolfram Perfecting the interface between you and your guitar.

wolframslides.com Endorsed by Martin Simpson and Tony McManus. |

|

#85

|

|||

|

|||

|

Hi, do you know what brand and type it was?

__________________

build, learn, grow Last edited by littlesmith; 05-18-2015 at 09:28 AM. |

|

#86

|

||||

|

||||

|

__________________

Wolfram Perfecting the interface between you and your guitar.

wolframslides.com Endorsed by Martin Simpson and Tony McManus. |

|

#87

|

|||

|

|||

|

Guitar 2 :

__________________

build, learn, grow |

|

#88

|

|||

|

|||

|

Welcome to the Klijnsmit musical instruments family, nr. 2!

Playing for the first time ever on the Klijnsmit Hybrid prototype 2.0. Just put the strings on a few minutes before this. https://www.youtube.com/watch?v=S2r9...ature=youtu.be Most accurate representation on headphones. I am very pleased with the sound, very rich, warm, clear and inviting to play on it. Still needs some fretwork and finishing, this is only a first playing test. Recorded with a xiaomi mi3 phone and the phones own mic. New recording with samson g track mic : https://www.youtube.com/watch?v=Awax...ature=youtu.be

__________________

build, learn, grow Last edited by littlesmith; 05-21-2015 at 07:35 AM. |

|

#89

|

|||

|

|||

|

Prototype 3 is under construction.

A nylon stringed guitar with modern neck width, white fabric and a black soundboard. Nickle plated tuners

__________________

build, learn, grow |

|

#90

|

|||

|

|||

__________________

build, learn, grow |

|

|

| Tags |

| tools vs craftsmanship |

|

|