|

|

#16

|

||||

|

||||

|

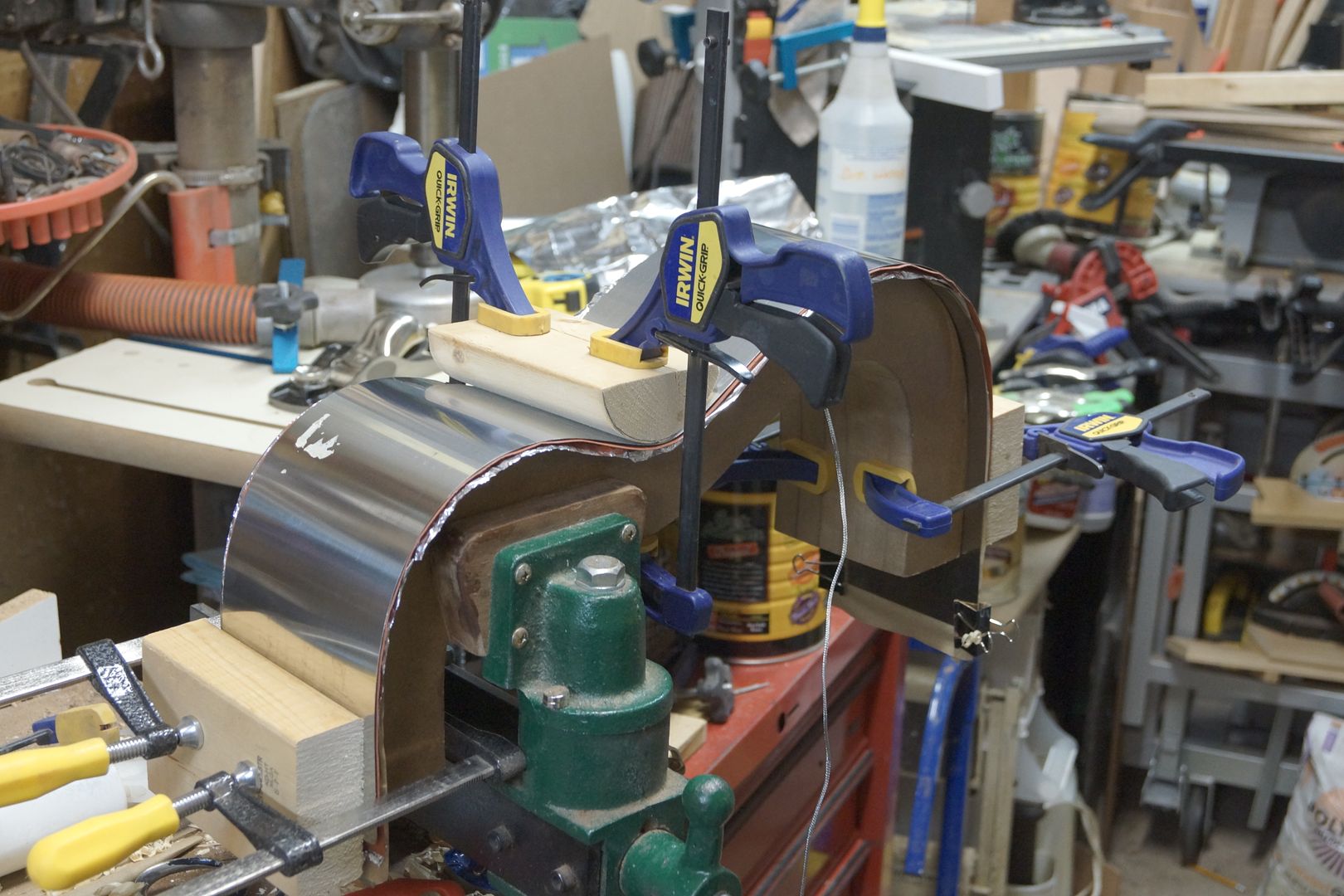

Bending with a blanket, on a form is really a great way to go. It's hard to get consistency with a bending iron, though I built my first 13 guitars that way. I still don't have a bending machine. I use a solid form I made with slats, a blanket, and some blocks of 2x4 and clamps. Works just fine. The bending iron is still used on all guitars, for rosette part bending, and touch ups on the sides when you get a little spring back or need to adjust a tiny bit.

Here's my bending system!

__________________

Waddy |

|

#17

|

|||

|

|||

|

Quote:

Quote:

Quote:

There is no right or wrong method, only individual preferences on how to get the job done. |

|

#18

|

|||

|

|||

|

That's a nice simple set up you got there Waddy. A good low cost way of getting into side bending jigs.

|

|

#19

|

||||

|

||||

|

I really don't have room for a bending machine! No place to put it during the 98% of the time I'm not using it for making a guitar. The form, is used for sanding (I also have an outside version for sanding inside), in addition to the bending. When I was bending with an iron, I used the form for checking my bends. blocks don't take up much room, and the clamps are used all the time during the process. Nothing wasted except the blocks, slats and blanket, but they don't take up much space. I actually liked bending with an iron, but hit a set of BRW that would not cooperate. It would twist every time I tried to adjust the bend on the iron. Finally straightened it out with an iron and used a blanket. Came out perfectly - no twist. Have not used the iron for a bend since, except for rosette purfs, a broken piece of binding or some extra purfling for the top or back.

__________________

Waddy |

|

#20

|

|||

|

|||

|

^ Did you factor in a little spring back when you make your forms?

|

|

#21

|

||||

|

||||

|

Just a little bit. I just guessed. It was all in the ends, not waist. I do re-bake my sides, which really cuts down on spring-back. Takes some extra time, but really helps. Some woods are more prone to it than others.

__________________

Waddy |

|

#22

|

|||

|

|||

|

Here's a really simple to make pipe bender including temperature control and the "mandatory" timer.

http://acousticguitarconstructionfor....php?f=8&t=794 An inexpensive 6" silicone blanket is the heat element. |

|

#23

|

|||

|

|||

|

Here's a really good video by Ad Van Kuijk using an electric bending iron and a shop-made platform to keep the bends squared up to the sides. I have found all of his videos very useful and well executed.

https://www.youtube.com/watch?v=qvsDcM0HaqU

__________________

Guitars: J-45 copy, Stahl Style 6 inspired copy |

|

#24

|

|||

|

|||

|

I used a couple bending machines when I was learning to build, but ever since I've only used a bending iron. Bending the sides that way is one of my favorite parts of the building process. I like that I can see, feel, smell, and hear everything that's going on while bending and it's very satisfying to me to have bent the sides that way when done.

I also use the bending iron to bend the binding and it's possible to get a very exact fit to the body which helps reduce the potential for problems when installing the binding. From a practical point of view, a bending machine and the forms needed for each body shape you make take up a lot more room in the shop than a bending iron does. For my shop, that's an important consideration. Also, when I come up with a new body shape, I don't need to make new forms for a bending machine. And a bending iron is a much smaller investment. |

|

#25

|

|||

|

|||

|

Quote:

|

|

#26

|

|||

|

|||

|

Some have used an electric BBQ lighter inside a pipe. I have used a pipe, use a blanket on a form without a bender. Lately I rough out the bend on a pipe and then clamp it in the form with the blanket and cook it to set the shape. End up with the same setup as Waddy, a caul for the waist and some blocks for the ends.

__________________

Fred |

|

#27

|

|||

|

|||

|

I enjoy the satisfaction given from doing it by hand

Steve

__________________

Cole Clark Fat Lady Gretsch Electromatic Martin CEO7 Maton Messiah Taylor 814CE |

|

#28

|

|||

|

|||

|

I'm real curious as to what mr snow is using these days. It's been 2 1/2 years since thread start and he's still chugging along in his shop, wonder what he decided...

|