|

|

#1

|

||||

|

||||

|

I had a little project today and thought I'd share the steps I use to make and install wood bridge pin dots:

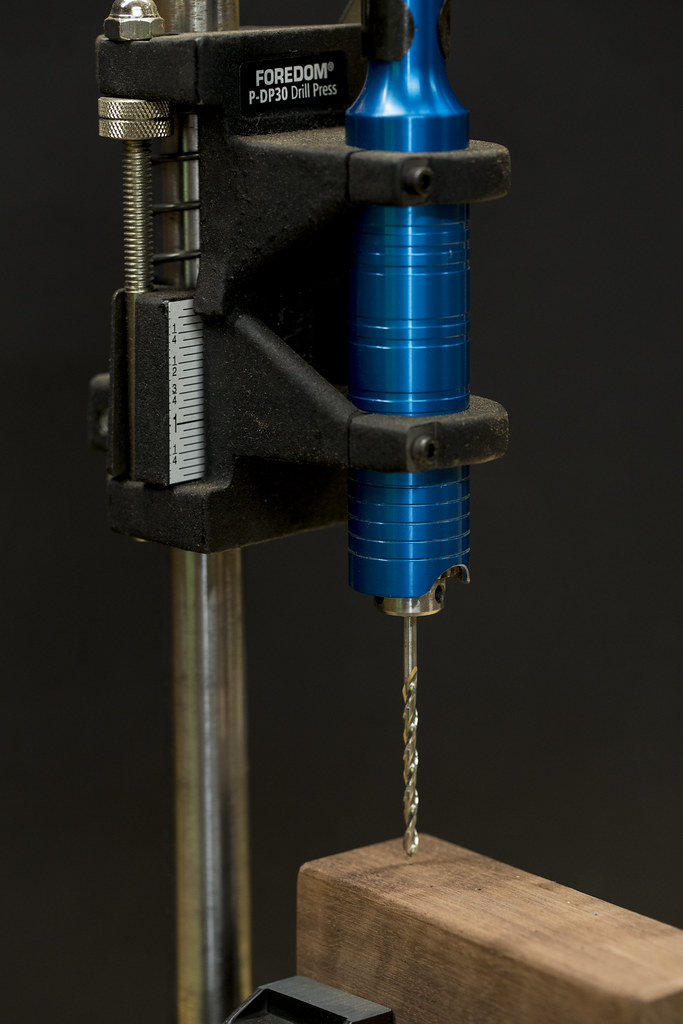

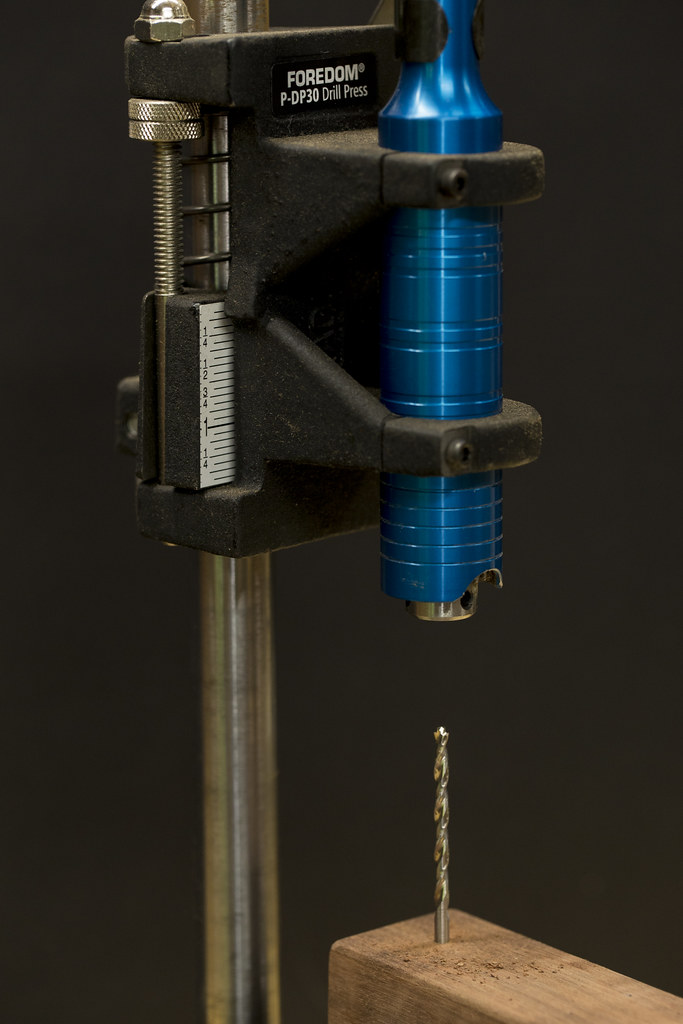

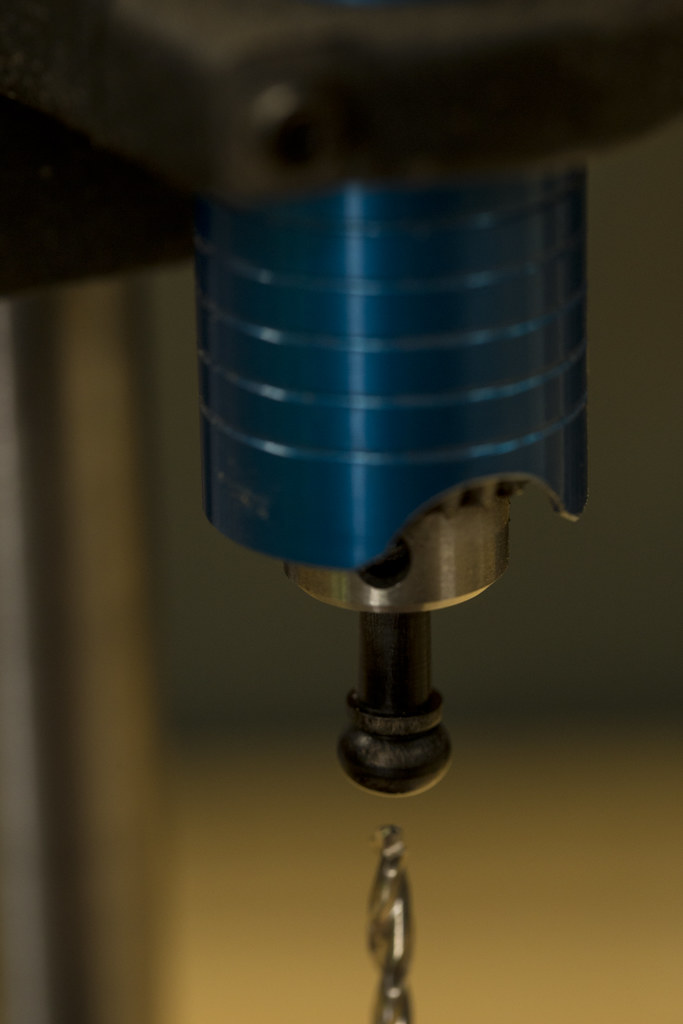

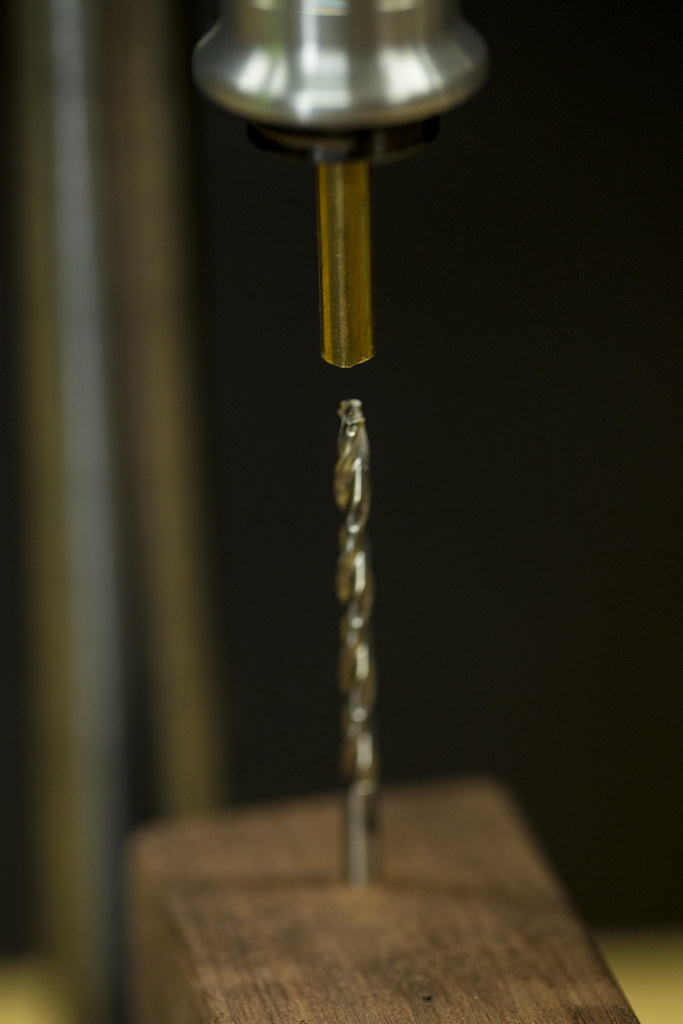

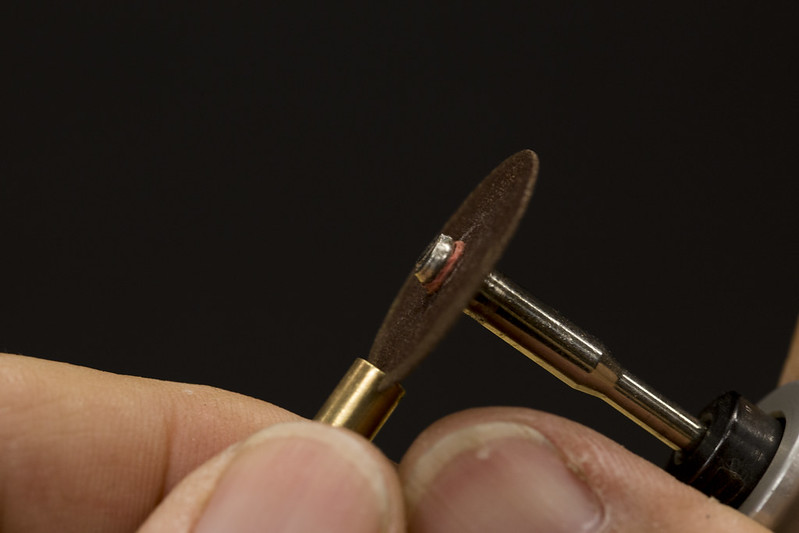

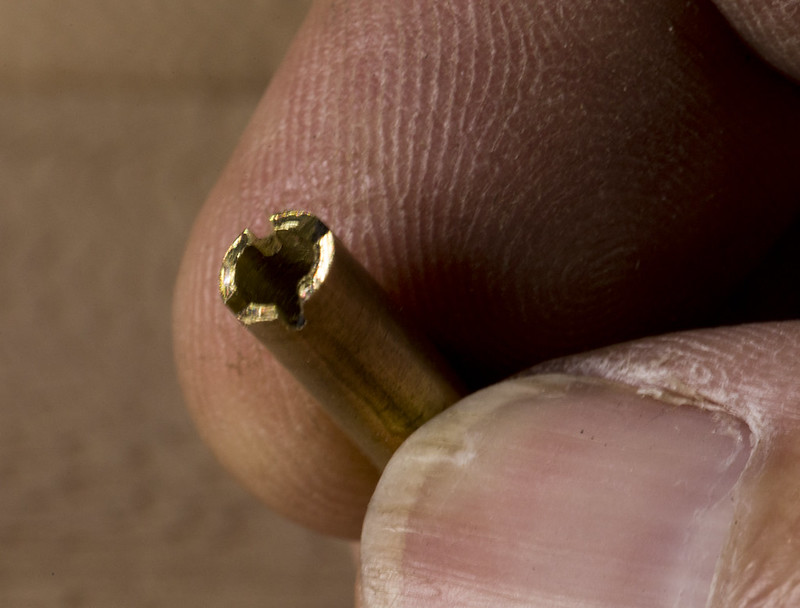

First step is to drill center holes into the pins to accept the dots. I am doing 1/8" dia dots so it starts with drilling a 1/8" hole into a little block of hard wood:  Then I remove the drill bit and stick it into the wood block point up:  Then I put the bridge pin into the drill chuck and spin the end pin not the drill bit:  This is the best way I've found to get a centered center hole drilled. The bit actually seeks out the center when it's done this way In this case I am putting Bloodwood into Buffalo Horn pins. You don't typically get away with the dots showing end grain because end grain doesn't shine and just gets dark. Wood plug cutters are often used to cut round wood plugs so the side grain shows:  Notice how I didn't show a picture of a 1/8" diameter wood plug cutter? Good luck finding one, I sure can't, so I'm going to make one. I'm going to start with a 3/16" OD thick walled brass tube I got from McMaster Carr:  You know how I'm going drill the inside out to 1/8" inch? That's right!:  I spin the tube not the bit. Good trick, works great! Now I need to give this some teeth. Doesn't need to be fancy, it only needs to work 6 times and I'll probably loose it before I need it again anyway:   Using a cutter with a hole all the way though enables me to stick something through the tube to pop the plugs out after I cut them:  Glue them in, clean them up, polish and I'm done!:  If you find this helpful and have any good tricks remember, you owe me! Mark

__________________

Mark Hatcher www.hatcherguitars.com “"A conclusion is the place where you got tired of thinking". Steven Wright |

|

#2

|

|||

|

|||

|

Definitely owe you one. That's ingenious. Thanks!

|

|

#3

|

|||

|

|||

|

Thanks a lot for posting this. Cool technique and good looking results. One question: how snug is the fit of the dots to the holes in the pins?

|

|

#4

|

||||

|

||||

|

Quote:

Mark

__________________

Mark Hatcher www.hatcherguitars.com “"A conclusion is the place where you got tired of thinking". Steven Wright |

|

#5

|

|||

|

|||

|

while i have easier ways to produce the hole in the end of the bridge pin, i do like the coring tool for making the insert.

thx for sharing! |

|

#6

|

||||

|

||||

|

Quote:

Many of these are meant for drilling core holes so make sure to get one with abrasive on the ID as well

__________________

Fazool "The wand chooses the wizard, Mr. Potter" Taylor GC7, GA3-12, SB2-C, SB2-Cp...... Ibanez AVC-11MHx , AC-240 |

|

#7

|

||||

|

||||

|

Quote:

Mark

__________________

Mark Hatcher www.hatcherguitars.com “"A conclusion is the place where you got tired of thinking". Steven Wright |