|

|

#211

|

||||

|

||||

|

Inquiring minds want to know....Steve, are you doing the armrest differently this time...I remember before seeing you cutting and bending one piece of wood for the arm rest, attaching, and then filing sanding into position....the use of the individual ebony tiles on this one????

__________________

PS. I love guitars! |

|

#212

|

||||

|

||||

|

Tom, we do them both ways. Sometimes to maximize the beauty of the grain; sometimes to maximize material use. With this jet black ebony, the material savings definitely outweighed the negligible visual distinction. Also, tiling looks attractive on its own in many types of wood, and it's easier to install. Your koa arm bevel benefited from the solid piece though. Don't you think?

|

|

#213

|

||||

|

||||

|

Quote:

__________________

PS. I love guitars! |

|

#214

|

||||

|

||||

|

Hey Tom, like Ryan said we do it both ways. For jet black Ebony it doesn't make too much sense to blow through a back panel to get a jet black "Nike swoosh".

These tiles do the job in a way very sparing of pricey resources. Here's one we did in Sankewood tiles for instance, which turned out well, and showed the figure to good advantage:  Thanks for checking in! Steve |

|

#215

|

||||

|

||||

|

Thanks Steve and Ryan for the explanation that I too had thought interesting to see the different approach on this one. Gorgeous work at EVERY level!!

One question, surely this doesn't pose a future risk of some kind of separation of the tiles? It seems that with the bending and variability or wood etc, that it might be more apt to future issues. Again, I very well may be and probably am wrong, and I am certainly not trying to be a critic nor do i want to rain on this gorgeous build, but trying to better understand how you guys get this stuff to stick permanently. I like the work you've done and you guys clearly have abundant experience in these areas and know what it takes to make something "built to last". But as Tom said "Curious and inquiring minds need to know"

__________________

"A good name is to be chosen rather than great riches, and favor is better than silver or gold." Woody (aka: Mike) FOR SALE: Kinnaird Brazilian!! |

|

#216

|

||||

|

||||

|

Quote:

Now--there are advantages and disadvantages to either type of bevel cap. But getting to your question, I don't worry about separation of the tiles--with perhaps the exception of serious trauma. Even then, I would anticipate something else would give way first in those unfortunate situations. And thanks for the kind word! Steve |

|

#217

|

||||

|

||||

|

Quote:

Quote:

Quote:

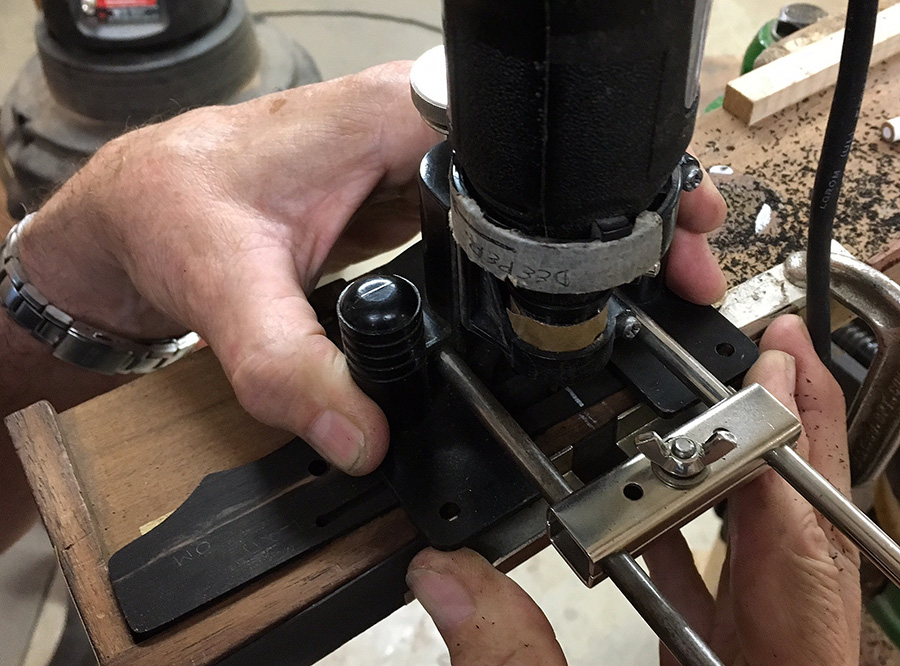

Piecing the tiles together on the bevel.  Filing down the bevel level with the top purfling.  Some scraping to get the bevel and top purfling absolutely flush.  The finished bevel. Man that looks comfy!

__________________

Life is like a box of chocolates .... |

|

#218

|

||||

|

||||

|

I have to admit when Steve and I first discussed the Lignum Vitae purfling with 1/3 sapwood and 2/3 heartwood to give a pulsed look, I was skeptical. Then we did a couple photoshop mockups of the rosette. I was completely on board. Now to see it implemented on the top is fabulous! And to see the process to getting there is intriguing too!

Here the slabs of Lignum Vitae cut from the block. These are approximately .055" thick, just shy of 1/16".  Then cut into strips with 1/3 sapwood, 2/3 heartwood.  Then each tile is cut to 1/16" wide and mitered at 45 degrees to give the herringbone effect (same as rosette).  The teflon spacer is removed from around the top.  And the tedious job of gluing in the tiles begins.    And voila! Awesome job Steve! Looks Beautimus!   And the fit around the cutaway horn couldn't be more perfect.

__________________

Life is like a box of chocolates .... |

|

#219

|

||||

|

||||

|

Oh my gosh is that gorgeous!

I have to sit down before I pass out!  Here that gorgeous fretboard meets the neck.  Relieving the heel on the neck. Ryan explains, "Essentially the end of the neck is flat and the OM still has a little curve at the neck block, so mating a flat neck to a curved body is a difficult task. To help the issue, we relieve the inside of the heel of some material - usually about 1/10" deep. We leave about a 1/8" ledge along the sides of the heel shape. This allows the neck to sit flush against the body instead of rocking on a high center. This one step does not completely solve the mating dilemma, but it gets us a fair way down the road."  The saddle slot is cut into the bridge.

__________________

Life is like a box of chocolates .... |

|

#220

|

||||

|

||||

|

That looks really really cool, to be able to make something so consistent from a natural color variation in the wood is awesome. Natural herringbone! It is a perfect touch on the guitar IMO.

__________________

PS. I love guitars! |

|

#221

|

||||

|

||||

|

Coming together superb....!!!

__________________

onedayatatime |

|

#222

|

||||

|

||||

|

Quote:

love that purfling!!

__________________

"A good name is to be chosen rather than great riches, and favor is better than silver or gold." Woody (aka: Mike) FOR SALE: Kinnaird Brazilian!! |

|

#223

|

||||

|

||||

|

Drool!!!! ..........

__________________

David Webber Round-Body Furch D32-LM MJ Franks Lagacy OM Rainsong H-WS1000N2T Stonebridge OM33-SR DB Stonebridge D22-SRA Tacoma Papoose Voyage Air VAD-2 1980 Fender Strat A few Partscaster Strats MIC 60s Classic Vib Strat |

|

#224

|

||||

|

||||

|

Thanks guys! Positive strokes always appreciated.

First radial purfling on Tom's OM, and now LV "herringbone" on Dennis'. We love it when the customer pushes us out of our rut. Steve |

|

#225

|

|||

|

|||

|

That's all really good work. Well done Mr. K. I REALLY like that it's all wood... as far as the appointments go. Really cool

Sent from my iPhone using Tapatalk Pro |