|

|

#31

|

||||

|

||||

|

Quote:

I don't do a lot of stuff ahead of time, but I do tend to make up brace stock (blanks) with the radius to match the back and top on the bottom of brace stock. They are very rough at that point. More work will be done when I grab them depending on the model I am building |

|

#32

|

||||

|

||||

|

Quote:

I use West systems epoxy, been good so far. |

|

#33

|

||||

|

||||

|

The top on the OM is White Spruce. It was cut about 30 years ago up in Canada and just recently made it to the states. I am excited about using this. Similar in properties as Englemann, and this set has a great tap tone. I didn't get a shot of any of the process of the OM's top being put together, but here is a shot of a sitka top that is going to be a GP (Grand Parlor.) More details coming on that later.

I am using a carbon fiber reinforcement on the upper face brace, and the soundhole patch is in place.  I did get a shot of the chladni pattern (ring-1/2 mode) when I was working the bracing on this top.  The OM is boxed up now waiting for binding. I might have to shelve this one for a little as I work on a couple of other projects, but I should be back on it soon. |

|

#34

|

||||

|

||||

|

What does this pattern tell you about the bracing John

__________________

Kinnaird Guitars |

|

#35

|

||||

|

||||

|

Hi John,

There is a lot of discussion on these methods out there in cyber space, and there are series of articles both the GAL big red books and in ASIA's guitar maker. Alan Carruth has done a lot of writing on this along with Marc Blanchard. I also wrote a (positive) review on Alan Carruth's DVD on free plate tuning for Guitarmaker a few years back. But to your question, what does this pattern tell me. The simple answer is, that I have the bracing where I want it. It is more about the shape than the actual frequency but I target the frequency based on empirical information too. In this case, the ring that formed is nicely symmetrical, fairly smooth. This is what I am shooting for. I use a symmetrical bracing pattern so this is easier to achieve than if for example I was using a Martin style X with the 2 diagonal tone bars. As mentioned there is a lot of information out there on this process. Some think it is hooey and many make better than fine guitars without it. I use this information to guide me, but better yet along with my spectrum analyzer, It helps me ear not to fool me and on top of that to keep records of each guitar. |

|

#36

|

||||

|

||||

|

I haven't made a (flattop) guitar with maple back and sides in over 15 years! I was going through my wood pile the other day and came across some sets I bought way back then. I thought hmmm, its time. This one is going to be a Grand Parlor model with a sitka top.

|

|

#37

|

||||

|

||||

|

Maple guitars from earlier in my career are vastly different different from the later (better) ones. I hope to hear you have a similar experience.

|

|

#38

|

||||

|

||||

|

Quote:

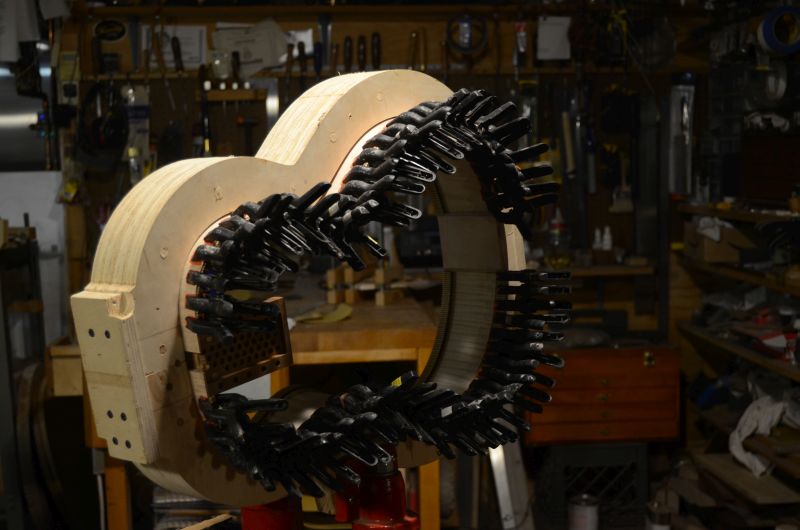

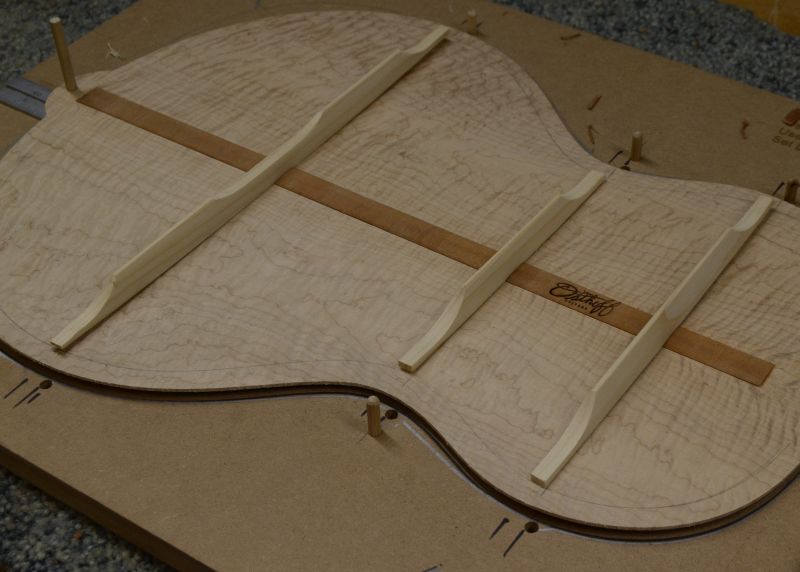

Here are a couple more (sporadic) shots of the Maple GP, In this first shot the rim is getting the linings installed,  Here is shot of the back getting ready to get the roughed out back braces installed.  Here is a little closer look at the branding

|

|

#39

|

||||

|

||||

|

Although I borrowed this shot from and earlier build, it shows the inner core of the composite bridge patch that I have been using. It sort of uses the I-beam approach for strength. A maple veneer is bonded to the one side and the top plate of the guitar makes up the other side.

|

|

#40

|

||||

|

||||

|

Very cool patch John. Do you make those yourself? It looks laser cut. How does the weight compare with a standard maple bridge patch? I have no doubt it's stronger.

My only concern would be drilling those string holes with some accuracy. Do you drill those holes from the inside before you put the maple veneer over the composit?

__________________

Kinnaird Guitars |

|

#41

|

||||

|

||||

|

Quote:

Thanks, yes I do make those and yes they are laser cut. The idea was derived from (an used with permission) from stuff Kevin Ryan does. I started doing these about 5 years ago and I had the all the weight numbers in my head to and spoke about them with authority at the shows. I don't remember the exact numbers but I think it was about a 40% reduction in weight. I bond the veneer onto the core before I glue the patch to the soundboard. Since I know the scale length etc, ahead of time, the bridge pin holes should land in the right place. Last edited by John Osthoff; 06-13-2016 at 07:17 PM. Reason: typo (or two) |

|

#42

|

|||

|

|||

|

Need to make a bridge the same.

__________________

Fred |

|

#43

|

||||

|

||||

|

Been busy in the shop for the past couple of days but I have not taken many pictures. I did come across one of the Cocobolo OM's Rosette. It is another one of my 'spirals,' this time with Buckeye Burl and Cocobolo.

|

|

#44

|

||||

|

||||

|

Here is another shot of the Katalox OM, with the body all put together.

I got the body bound up earlier this week, photos coming soon. |

|

#45

|

||||

|

||||

|

The back set is simply stunning John...

. I can't wait to see it under finish! . I can't wait to see it under finish!Kudos

__________________

A bunch of nice archtops, flattops, a gypsy & nylon strings… |