|

|

#1

|

|||

|

|||

|

I have some holly that I want to cut into bindings and I'm looking for tips.

It seems easy enough to cut strips on the tablesaw, but making an 1/8" kerf to get a .08 binding seems wasteful. Any tricks of the trade? |

|

#2

|

|||

|

|||

|

I use a 40 tooth skilsaw blade on my tablesaw which cuts about a .06 kerf.

|

|

#3

|

|||

|

|||

|

I use a tabletop bandsaw, mine is a three wheel Craftsman. The kerf is much smaller than 1/8", and it cuts that thickness easily. You can find them used for $100, and they are quite useful.

__________________

Rodger Knox, PE 1917 Martin 0-28 1956 Gibson J-50 et al |

|

#4

|

|||

|

|||

|

Photos please. Interesting subject.

Ed

__________________

"Quote The Raven, NEVERMORE !" |

|

#5

|

|||

|

|||

|

I resaw a plank on a big Aggie bandsaw, then thickness-sand the leaves to my spec., then cut to height on a three-wheel bandsaw with a very narrow blade.

I also have a micro-table-saw I can use for the operation. It uses .031 blades. As I recall I got that saw dirt cheap at Harbor Freight.

|

|

#6

|

|||

|

|||

|

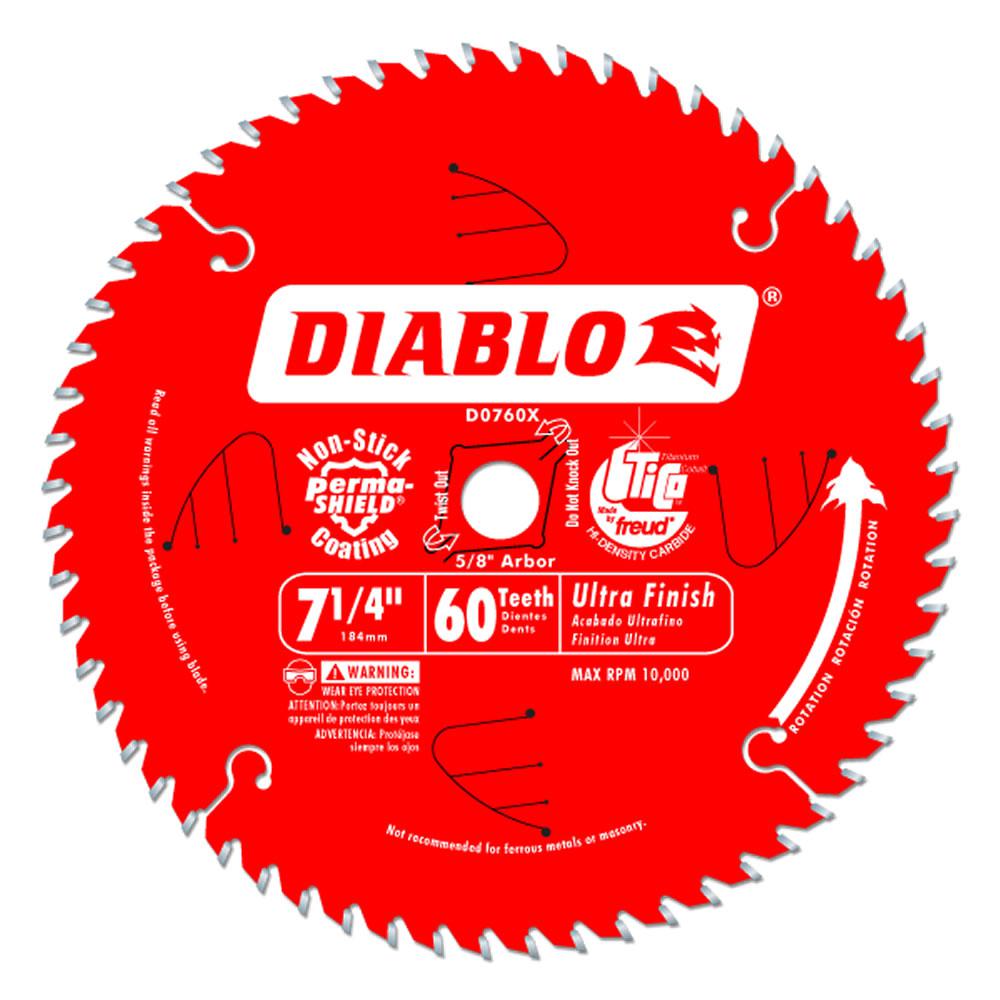

This. .059" kerf.

__________________

"Still a man hears what he wants to hear, and disregards the rest." --Paul Simon |

|

#7

|

|||

|

|||

|

Is what it is, many processes are wasteful in building a guitar, from resawing wood for tops / backs and sides to making binding.

Just use what you have and cut as many as you can Steve

__________________

Cole Clark Fat Lady Gretsch Electromatic Martin CEO7 Maton Messiah Taylor 814CE |

|

#8

|

|||

|

|||

|

Around here holly grows all over and some folks will certainly let you cut it. so if it's free, what the heck?

|

|

#9

|

|||

|

|||

|

I usually cut off the bindings from the side set before bending, then add purflings and glue them back where they came from.

I use an old fret slotting blade. It smokes, but it cuts, with almost no waste at all. |

|

#10

|

|||

|

|||

|

Yes.... I got that tip from Mario Proulx at the MIMF. Didn't believe it myself until I tried it. With a zero clearance insert, I can cut down to .040" with reasonable consistency and relatively clean, only needing a little scraping to smooth out the saw marks.

Also great for general ripping if it's not too thick a stock; the thin kerf doesn't bind, and with a tablesaw's horsepower it cuts through like butter with very little noise, which equals very little vibration very smooth cuts... |

|

#11

|

|||

|

|||

|

I think the question is, where does one find holly that's clear enough for the length needed for binding! Everything locally looks great, until there's a knot...

|

|

#12

|

|||

|

|||

|

Everything is great, until it's knot.

|

|

#13

|

|||

|

|||

|

My experience with holly in boatbuilding is that it quite unstable and prone to twisting and warping. May not be too bad for binding, but being able to cut a 32 or 64 inch length might be difficult.

Ed |

|

#14

|

|||

|

|||

|

I use a razor knife. I will resaw off a QS veneer of what ever wood I am using and finish it to 1/8in thick. Then clamp it down on a work board with a long straight edge. Then with a fresh blade on the knife score a line along the edge and go deeper and deeper till it pops off. Usually takes 5 or 6 swipes.

Pretty much zero waste with that method. |

|

#15

|

|||

|

|||

|

Holly gets blue sap stain very fast when cut in the summer; you must dry it fast. I cut down a 4"-5" section about 18" long this spring for making a red, white, black, block to cut and sandwich between veneers. Cut into 3x16"x 1/2" sections and microwaved. dried it over two days but still got a gray stain. Might still use it but not what I was hoping for. In Atlanta I have only found holly veneer, no 1/4 or 4/4 to cut up. Buy veneer don't cut that up. Holly and blood wood go great with black dyed veneer. I found plenty of 4/4 blood wood but no veneer. I cut blood wood into 1/16"-1/4"strips off the side of board. Over half goes to sawdust. Blood wood is Very hard. White can be maple.

|