|

|

#1

|

|||

|

|||

|

Ok gang, as an amateur builder I KNOW that there are a bunch of wonderful tools that the pros use and would be lost without, but us sawdust makers aren't going to stump up for!!

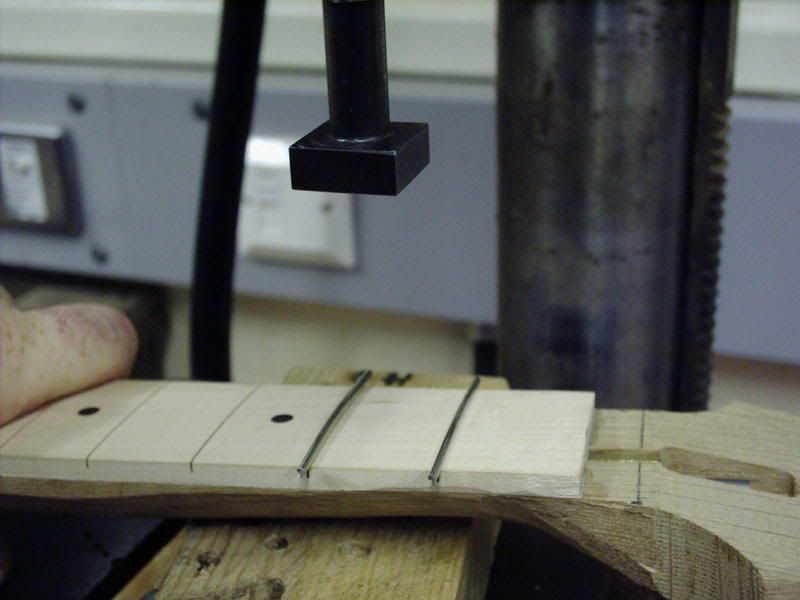

things that I'd be lost without are a bandsaw, router, pillar drill and sander. thankfully the highschool that I teach in has all these things.... OK where to start..... side bending. a fox bender is great if you are going to make 30 identical guitars. A hot pipe from one of the main supplies houses is GREAT, but can be worked around. I made my first 10 or so using walnut, and a steam wallpaper stripper.  I steamed the sides and then forced them into moulds with clamps. Walnut bends like butter so this worked fine, also worked well with oak, but when I started looking at other woods I needed a hot pipe. so I got a piece of scrap aluminium tube, blocked the end and heated it with a hot air paint stripper. worked PERFECTLY, though it did eventually burn out the air gun......  forcing the radius of the top & back. yes, it's NICE to have a nice big dish, but is it needed? nah!! so long as the braces are shaped to the right radius then a bunch of clamps will pull the top or back round to fit  the big advantage of this is that you can vary the radius without having to buy (or make) a new dish. don't have a long reach clamp? then clamp your back braces using two long planks, one above, one below. use wedges if needed.  fret press? nah, until recently I used a big old T bolt and the pillar drill.....  more to follow!!

__________________

Quote:

|

|

#2

|

|||

|

|||

|

Thank you for this thread Martin.

$$$ are short these days. |

|

#3

|

|||

|

|||

|

Wow!! Just in time. I have been scouring the web for just such tips. Do you have any links to plans for specialty jigs, clamps etc? I did find this one for cam clamps.

...keep'em coming! |

|

#4

|

|||

|

|||

|

cam clamps are lovely, but they're not cheap and they are really only good for nice clean luthier jobs. I use mine all over the place.

the only speciality clamps I have are the ones in the braced top pic above. they came from Stewmac at about $8 each I think. the rest are just clamps I got in B&Q (our version of Home depot). The friction ones like mastic guns are great, very strong, one hand operation, but strong enough to go straight through a top, so be careful!! I do like having a few REALLY long ones. I have 4 that are used for door frames, like a yard long, which are great for a bit of extra squeeze on bindings in tight curves or on the tail wedge or even glueing in the neck.......  Oh yeah, bindings. clothes pins. a bag of plastic spring action clamps cost what? $2 from a budget store? they work GREAT! and afterwards you can hang up your freshly laundered underwear!

__________________

Quote:

Last edited by martinedwards; 02-10-2010 at 11:32 AM. Reason: pics added |

|

#5

|

|||

|

|||

|

Oh yeah, I've seen folks spending longer making the body mould than I spend making a whole guitar.

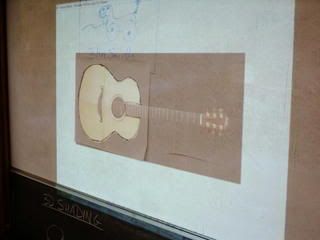

sorry, but there is NO REASON to sand the inside of a mould. so long as it's PRETTY close, it'll be grand!! buy plans? NO!! get access to a data projector (I'm a teacher so I have one in my classroom) and project your fav guitar body onto the wall. set the magnification so that the scale length is right, then draw round it.  it works with bracing patterns too.

__________________

Quote:

|

|

#6

|

|||

|

|||

|

Martin,

Cool tips. I am a teacher as well and can project a picture, but how do I know the scale measurement? Is it a matter of pulling the info from the manufacturer's website, or is "scale length" a term I should learn? Thanks |

|

#7

|

|||

|

|||

|

scale length is from nut to bridge.

to be REALLY fussy it's nut to saddle on the thinnest string minus the thickness of that string. but given the resoultion of projectors that schools use (we're not HD!!) just the raw length will do. if you're doing a martin D18 then its 25.4" or 645mm either go to you fav supplier and buy a preslotted fretboard of that scale or go to here and it'll calculate the fret spacing for you to cut them yourself.

__________________

Quote:

|

|

#8

|

|||

|

|||

$50.98 plus postage. or  $8.10 INCLUDING postage from Hong Kong on eBay OK, theres no fret height groove on the end, but is it worth over $40? not to me!! I have just got my second of these as my first died after 3 years hard use.

__________________

Quote:

|

|

#9

|

|||

|

|||

|

Love this thread. What do you use to clamp tops/backs to the sides when gluing?

|

|

#10

|

|||

|

|||

|

prettyyy coollll ehhhh?

__________________

La Traviata Tickets |

|

#11

|

|||

|

|||

|

clamps for tops & backs?

the same one handers I use for the neck & tail blocks, neck laminations, fretboards, headstock scarfs, and every other job!!

__________________

Quote:

|

|

#12

|

|||

|

|||

|

router for binding?

OK the binding cutter from any of the luthier suppliers is $45 or so.......  I use these now but my first binding was done freehand with a dremel in a router stand.  takes TIME and a strady hand but if you're only going to make one guitar, then a dremel and a stand (get the stewmac stand, it's a similar price to the dremel one I bought, and more flexible) will do a load of the jobs for a fraction of the cost of a router. but, like I said, I now use a router. but I don't like jigs and usually go freehand!!

__________________

Quote:

|

|

#13

|

|||

|

|||

|

Do you use a router freehand or did you make a binding jig?

If you don't mind I've sent you a PM regarding a few things. |

|

#14

|

|||

|

|||

|

for binding now I use a router and the cutter from Stewmac. handheld with no fancy dancy jig. never saw the point.

I'll now go look for the PM!!

__________________

Quote:

|

|

#15

|

|||

|

|||

|

I think that's how I will be doing it. I got a Stew-Mac binding set from eBay. The only shame is my router is 1/2" collet and I need a 1/4" one.

|