|

|

#136

|

||||

|

||||

|

Well, I used the belt sander for a "rasp break" for my hands! Any pressure on the belt and it slows down or quits. I did some shaping pretty easily with a 1.5" 80 grit belt, turned inside out and I was the "oscillating" motor. I am enjoying the hand shaping but by #3 or #4 I think I will be over it and ready to use a belt sander (that works).

The neck has really taken shape. Later today I will sand out slight humps and dips. I am thinking I may bolt down the fretboard to the soundboard ala Bourgeois and Mayes style, instead of gluing. Not sure yet. |

|

#137

|

|||

|

|||

|

LOL - I'm almost sorry I talked you into doing a maple neck! It's gonna look great though.

|

|

#138

|

||||

|

||||

|

It's cool. The Martin Spanish Cedar dings if you look at it. This stuff shrugs off a rasp! BTW I wanted maple, but did not want to buy it. Then I found this 3 piece hunk in the scrap pile. Inspired by availability!

|

|

#139

|

|||

|

|||

|

Quote:

For the neck itself, I almost destroyed a spokeshave but was able to get it close. And to level out dips, I had self-adhesive 80 grit sand paper and taped it to a flat 3" x 18" x 1" board. I then used it as a flat file to round out the neck properly in a figure 8 motion. I saw Somogyi do something similar in a video and thought it a good idea. It worked like a charm. I then smoothed it out with progressively finer sand paper just wrapped around the neck going along the grain. By the way, I'd go with maple any day of the week over ABW. Man, that is one dense wood! Working the binding on my guitar, which was maple, was an absolute pleasure compared to working with ABW, lol!

__________________

Chris Wong Guitar Slim Dred Adi/Bubinga Chris Wong Guitar Slim Dred Adi/ABW (Just done!) Martin LXME Ibanez ATK700-BM ZT Acoustic Amplifier Psalms 108:1-3 |

|

#140

|

||||

|

||||

|

Quote:

The main rasp I used had belonged to my Dad. Never saw my Dad do a lick of wood work, but its cool it was his. For Sanding blocks I use some old Preschool Maple Community Toy Building blocks I scored at a Flea Market. Dead flat and pretty much bullet proof. So I am on day 3 shaping the neck. Yesterday I had to put a pillow at my lower back so I could drive. This morning I was on Kevin Ryans site. He has a custom router bit for shaping the heal and another jig for evening it out. Looks like he does in 2 minutes what will take me another 10 hours lol. Wouldn't ABW be a really heavy neck? |

|

#141

|

|||

|

|||

|

Are you looking at the table-type oscillating spindle sander? You know I have need for that. One thing that might suit it a reconditioned Ryobi Routing Table (it's a pretty small table though) at that reconditioned tool outlet down there at the Tangers Outlets. That particular model was $70. I was looking at just the 1.5hp router for $40 but for another $30 why not go with the table too? IIRC it shouldn't be too much of a problem hooking up a spindle to a router right?

As for the thickness sander, all in due time. I know it's got you frustrated and I don't want you to feel rushed. There are more important things to worry about. |

|

#142

|

||||

|

||||

|

Neil, don't stay away from the work bench too long. If John gets a strange call, he will know it is the bench because it is missing you.

Benches become personal friends of luthiers. It will hear more insider secrets when you wood workers talk out loud.

__________________

... make a joyful noise ... http://www.mcknightguitars.com AGF MCKNIGHT GUITAR SNIPPETS https://www.acousticguitarforum.com/...d.php?t=663228 I'll continue "Doin' Life ... As a Luthier's Wife" McJam = Guitar private event June 21-22, 2024 [email protected] Pre-sign is required and begins now. |

|

#143

|

||||

|

||||

|

Protecting the top

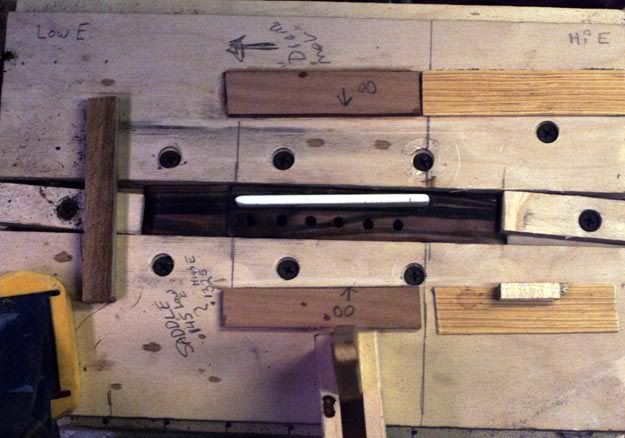

She is taking shape! Ow! My back!  Rasp when sand paper doesn't cut it.   Here is the mostly complete Bridge pinhole and saddle jig (pin hole adapt not pictured)

|

|

#144

|

|||

|

|||

|

Quote:

Seriously, get a spokeshave, even a cheap one will do. The only thing you'll be frustrated about is why you didn't have one or spend $15-20 on one for the first 15 hours, lol!

__________________

Chris Wong Guitar Slim Dred Adi/Bubinga Chris Wong Guitar Slim Dred Adi/ABW (Just done!) Martin LXME Ibanez ATK700-BM ZT Acoustic Amplifier Psalms 108:1-3 |

|

#145

|

||||

|

||||

|

CW I will put it at the top of my list!

|

|

#146

|

||||

|

||||

|

very cool thread! I applaud the effort!

Love the rosette....

__________________

_______________________ Peter M. Cornerstone Guitars www.cornerstoneguitar.com Ukuleles... www.cornerstoneukes.com |

|

#147

|

||||

|

||||

|

HI Guys!

A lot has happened fast. 1) my Photography Biz is in full swing! The summer was fatal for biz. So, the build will slow down. Tonight, I am hoping to get the nuts in the neck for the MT 2) I got my first commission to build a guitar! #2 complicated things for me I wanted from the start to sell my creations. Probably not this fast. But, tools don't fall from trees! I was very straight forward with the buyer of #3 that I still have much to learn. He wanted #1 "the Fish" bad! He played her no less than 3 hours. A big Allman Brothers fan. Sweet Melissa sounded very sweet on the Fish. Wow the guy could play. My bracing and light guitar took and held to quite a "beating". He plays loud and sings loud. I told him a family trip to Disney would be the only way my wife would let her go. He said; too steep! So, he commissioned #3. He wants her backward and everything! The commission changed my dynamic though. In the technical sense I am now a "Pro" NO. I don't think I am up to par with the big boys. But! I do work to be better every day. To journal #3 here and stay on the up and up I had to go "Sponsor" I have also been advised to change my name to my fledgling guitar company. So....... Yamaha Junkie will soon become; Kitchen Guitars Sponsor formally known as Yamaha Junkie I also snagged Kitchenguitars.com When I know what I am doing with it I will let you know! Mean while enjoy watching me try to keep my fingers! |

|

#148

|

|||

|

|||

|

Quote:

Looking forward to seeing pix of your first commissioned build! |

|

#149

|

||||

|

||||

|

Quote:

|

|

#150

|

||||

|

||||

|

Hey, John... I had to look.

This is what I found. Cigar box guitar.  http://www.youtube.com/user/KitchenGuitars

__________________

... make a joyful noise ... http://www.mcknightguitars.com AGF MCKNIGHT GUITAR SNIPPETS https://www.acousticguitarforum.com/...d.php?t=663228 I'll continue "Doin' Life ... As a Luthier's Wife" McJam = Guitar private event June 21-22, 2024 [email protected] Pre-sign is required and begins now. |