|

|

#1

|

|||

|

|||

|

Proble #3 of 1000 for my build. The rosewood back plates are uneven. They appear thinner in the center as you go lenghtwise. How can this be dealt with? Just plane and sand, plane and sand? They are fairly thick so I have room to work the problem.

Best I can describe is that it appears the band saw drifted or twisted as the wood was resawed, leaving a dip in the middle. Is this a deal breaker for the wood? Is there such a thing as a deal breaker for the wood? |

|

#2

|

|||

|

|||

|

Any chance that you have a caliper?

__________________

Fred |

|

#3

|

||||

|

||||

|

Its only a deal breaker if it’s thinner than your eventual target. If I were going for .075” I like to have no less than 0.085” . You have to pay close attention to where your thinnest spot is both in the glue up and in the thicknessing, but it doesn’t have to be a problem.

|

|

#4

|

|||

|

|||

|

Quote:

I always rough sand the backs to an even thickness on a drum sander before doing any joinery, example if I want a 2mm back, I will drum sand each piece to approx 2.2mm before joining, then after joining I typically plane and or scrape it down to desired thickness and tap testing it whilst thinning. Steve

__________________

Cole Clark Fat Lady Gretsch Electromatic Martin CEO7 Maton Messiah Taylor 814CE |

|

#5

|

|||

|

|||

|

...unless you have a drum sander for this task.

It’s much harder to successfully join two plates when they differ in thickness. And I find it easier to glue the plates and then take to final thickess. As already stated above you only have an issue if the current lowest depth is very close to, or less than the final required depth. When planing thin plates of wood I find this needs to be done on a known flat surface, such as a piece of kitchen worktop. Any unevenness on your bench can make getting a plate even across it’s length very tricky indeed. My preference is to take the thickness down to 3.5 or 4mm, glue, and then do the final thicknessing. Of late I’ve been gluing top and back plates using what I think of as the ‘stretched tape’ method rather than clamps or a jig. The result is every bit as good and it’s much quicker. Hope this helps. |

|

#6

|

|||

|

|||

|

Quote:

I just can tell I may have trouble when thicknessing now or later. Either end of the 2 pieces is about a 5-6mm thickness, but the middle of each piece (each half/plate) goes down to 3-4mm. The material removed will be what it is going to be in respects to saw marks. Those have to come off of both sides. I will forgive some in the interior of the piece but the outer guitar is unacceptable. Hope that clears up some? They are not joined yet. The other fortunate thing with this is that I was smart enough to buy a dread back but am building a 000 guitar. Have quite a bit of material to play with before I am changing plans to a parlor.  In addition the other set of back plates that I have are cut better. These were won as an accident, (I knew I'd get sniped)but they are my plan B. |

|

#7

|

|||

|

|||

|

Trying to look at it as a positive. This will be a success or some expensive practice and any backs I join in the future I will have had this problem, so they should be easier.

|

|

#8

|

|||

|

|||

|

If your plan is to thickness with a handplane, then you need a very flat surface for reference - cheapest is an off-cut of stone countertop, but a nice piece of coated shelving can work fine. Attach a couple stops - with double stick tape on stone - preferably something that won’t dull your plane blade if you accidentally hit one.Then a long sole, very sharp handplane. Put the flattest side down, then start working down the high spots. Flip it and work on the high spots on the other side. You should see pretty quickly which side will be the best outside, which will be best inside. But you need to do both pieces and check them against each other frequently. Depending on grain, its probably easiest to plane close to final thickness before joining. Once glued together, you may be limited to sandpaper and scrapers to avoid tear-out. I’m hoping you have a good straightedge and made or purchased a decent thickness guage?

__________________

More than a few Santa Cruz’s, a few Sexauers, a Patterson, a Larrivee, a Cumpiano, and a Klepper!! |

|

#9

|

|||

|

|||

|

Quote:

Plan WAS to hand plane. My first set of plates are a bit too pretty for a beginner. Some figuring and knots in the wood that are well placed. Couple that would with my planing technique and the result was some moderate to awful tear out. In comes the lowly scraper. It is taking forever but I enjoy the scraper. My sides have much less figure to the grain so I will give planing a try again. Good straight edges are covered. Got plenty. My thickness calipers are awful. A better tool is on my list. |

|

#10

|

|||

|

|||

|

Lowly scraper?!? Au contraire! Check out the Stanley #80, or even the #112, scraper planes - they are marvelous tools, and very capable of bringing highly figured materials flat and smooth with little or no tear-out, and work equally well with straight grained material as well. Develop good skills with those, and you would be well served - Kunz makes modern reproductions if you cannot find the older Stanleys -

__________________

More than a few Santa Cruz’s, a few Sexauers, a Patterson, a Larrivee, a Cumpiano, and a Klepper!! |

|

#11

|

|||

|

|||

|

Quote:

Been there, done that. And for a long time. Then tried various "technologies" to circumvent my inability to effectively use hand planes, including ridiculous amounts of hand sanding, scrapers, thickness sanders... I eventually obtained instruction by experts in the field of hand tools and wished I learned those skills many years earlier. My suggestion is to save yourself a lot of trial and error, wasted materials, blood, sweat and tears and simply learn from experts how to sharpen, setup and "fettle" hand planes. When I first started, and for years thereafter, the information wasn't readily available. Today, with Youtube, on-line courses, on-line forums, etc. the information is widely available and relatively inexpensive. I can understand that you might just want to get the job done on a first or second instrument, but, at some point, one really needs to learn the requisite skills needed to do effective woodworking. Sure, for many tasks one can circumvent that, as I did, by using other methods, but one pays the price for doing so, even if only in added effort to complete the task. There are lots of ways to perform any given task, but some are quicker and easier than others and developing skills allows one a greater pallet from which to chose. |

|

#12

|

|||

|

|||

|

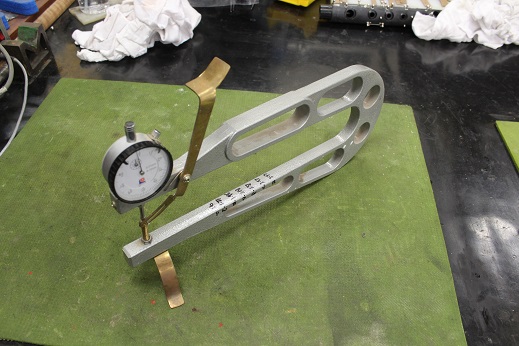

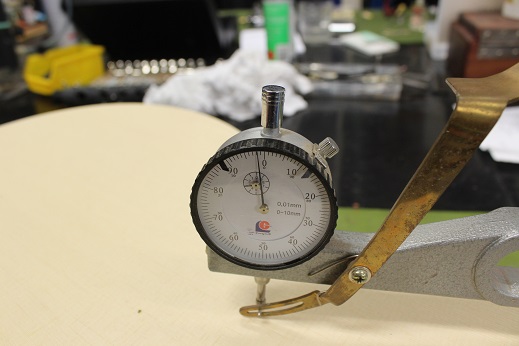

Quote:

Steve Tool is sprung loaded closed, so no playing required of pressure  Top just made  2.98mm

__________________

Cole Clark Fat Lady Gretsch Electromatic Martin CEO7 Maton Messiah Taylor 814CE |