|

|

#1

|

|||

|

|||

|

i've been wrestling with side purfling on my first five guitars. a few questions for the builders out there - 1) what kind of glue to you use to glue up your side purflings and to glue the purflings to the binding? 2) how do you go about bending the purfling/binding combo 3) do you bend the purfing already glued to the binding or separate?

i've been going over somogyi's book and he states that he bends the side purfling separate from the binding. but i can't seem to make sense of this. the inherent trouble with side purfling is that you're trying to bend it along it's tallest axis, without allowing to cave in or tip over, if that makes sense. ryan gerber www.facebook.com/gerberguitars |

|

#2

|

|||

|

|||

|

1. Titebond.

2. hot copper pipe or Fox-style side bender. 3. Bend after side purfling is glued to bindings. Other than if one uses too much heat during bending the glue holding the side purflings together and to the binding can let go, I can see no reason to bend the purflings separately. I think it much easier to glue first, then bend. YMMV. Lutes often have spacers between the ribs of the back. These are bend on edge (i.e. tall axis). A trick I learned years ago was to attach two pieces of copper pipe to the outside of my bending pipe. The two pieces are a little more than half circles of the same diameter as the base pipe, but sprung to fit snuggly over the base pipe. (You can cut an inch or two off the end of the bending pipe to make the two pieces.) The pipe wall thickness is maybe a 1/16" or so. The two half rings are placed on the circumference of the pipe separated by the width of the purfling to be bent. The two half rings support/sandwich the purfling during the bending. It makes it fairly easy. |

|

#3

|

|||

|

|||

|

While taking Charles Foxs' acoustic guitar building class last year we used Titebond and "THE" Fox bender.

Worked great. Just have to make sure they are in the correct orientation in the side bender so you have R & L sides. (They were glued up prior to bending.) Worked great. Just have to make sure they are in the correct orientation in the side bender so you have R & L sides. (They were glued up prior to bending.)

__________________

Steve |

|

#4

|

|||

|

|||

|

Quote:

I tried it that way once, and other than gluing my fingers to the binding, it worked very well.

__________________

gits: good and plenty chops: snickers |

|

#5

|

|||

|

|||

|

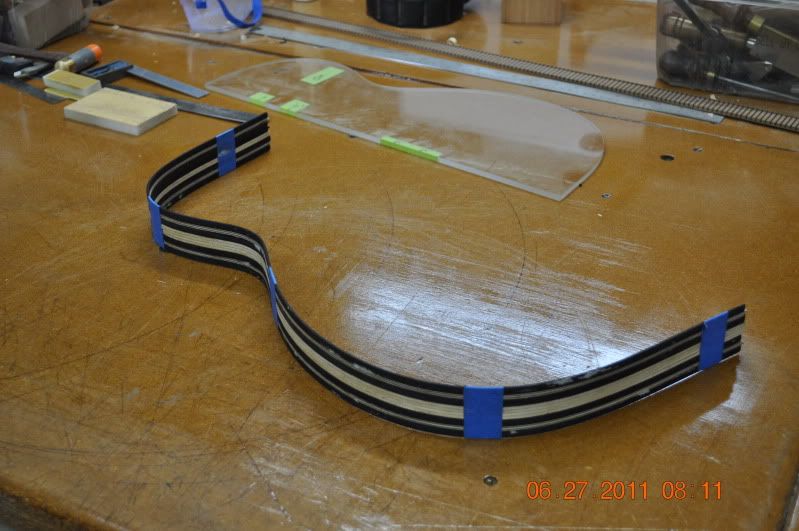

i have been using my side bender, with the binding strips taped together as tight as possible, wrapped in foil with plenty of water in the foil. a few observations that i've made: 1 - if they are taped too heavily, and the steam is not allowed to penetrate the wood, they crack in that location. 2 - CA glue seems to hold up under heat better than Titebond. 3 - after using these methods, and bending at about 325 degrees F, i'm still getting too many causalities. which is a real bummer when using an expensive wood like ebony, and after taking the time to glue them up.

what is your success rate? do you bend with water or no water? and at what temp? good to see the replies! ryan gerber www.facebook.com/gerberguitars |

|

#6

|

|||

|

|||

|

Quote:

FWIW my only experience with bending this far has been with mahogany, which I'm told is a good first wood to bend with and at 290-300 degrees F it went very easily (over 4 attempts!) Now I'm about to bend some Indian rosewood binding with BWB purfling though and I wondering if we need to make things a little hotter but like with the OP I'm not sure - though I'm fortunate to not have been "burned" in the past. I was also told that because Titebond will loosen up when heated that it would be better to just install the purfling separate. Is this not true - or at least partly true? I'm thinking that if the purfling is glued to the binding and comes apart under heat, then at least they both will get bent anyway so that you can just reglue everything together in the binding channel. Am I right in assuming this?

__________________

(2006) Larrivee OM-03R, (2009) Martin D-16GT, (1998) Fender Am Std Ash Stratocaster, (2013) McKnight McUke, (1989) Kramer Striker ST600, a couple of DIY builds (2013, 2023) |

|

#7

|

|||

|

|||

|

Quote:

I Dampen the surface prior to putting in the bender; no foil; taped together in four or five places; hot enough that water put on the metal slats at the waist sizzles - I don't use a thermometer. How thick are your bindings? Are you selecting wood with minimal runout for the bindings - that can make a big difference. |

|

#8

|

|||

|

|||

|

Quote:

If on a Fox bender, when the water sizzles at the waist. Again, the bending of the wood tells me the pace at which to bend. I generally use one heat setting - full blast. It seems to work well regardless of wood type. Quote:

Others may have different experience. |

|

#9

|

|||

|

|||

|

[QUOTE=

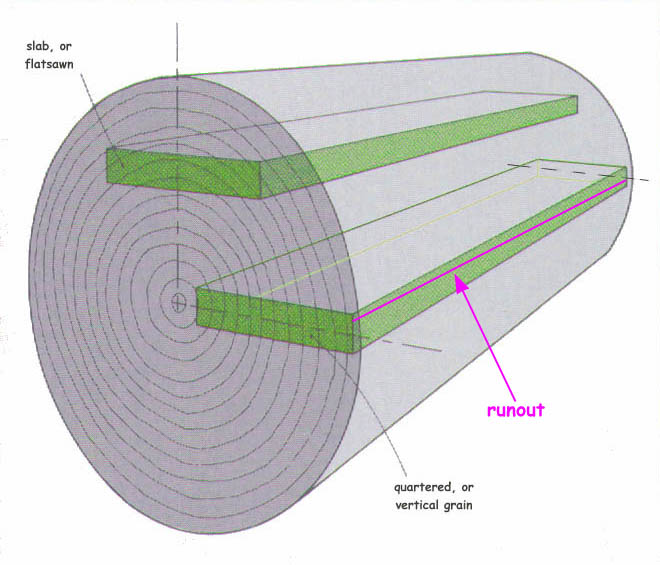

How thick are your bindings? Are you selecting wood with minimal runout for the bindings - that can make a big difference.[/QUOTE] my bindings when bent are 7/64" as for selecting pieces without runout, i'm not aware of how to do this. what does runout look like? |

|

#10

|

|||

|

|||

|

Quote:

From http://www.lutherie.net/frankford.runout.html. I'm not suggesting that you split the wood from which to make bindings. But, choosing wood with little/no runout can be the difference between success and breakage. |

|

#11

|

|||

|

|||

|

Way too thick. Try .080".

|

|

#12

|

||||

|

||||

|

I spent 2 days messing with a complex binding with spacers and rope Purfling. After it was bent I threw it out. Stuff slid, grain patterns did battle...... Neil saw the mess

One at a time for me. I tape them down directly to a steel blanket. Spritz with water, put on another blanket and go to the bender. As far as attaching. Best luck I have had has been Titebond for the working time. Also, the Stew Mac Binding tape has produced my tightest adhesion by far. Especially in the waist. |

|

#13

|

|||

|

|||

|

For bending purfled bindings in a bender it's a good idea to tape them together in pairs,purfling to purfling.This helps prevent collapse of the purfling and ensures a set for top or back. I use titebond for gluing purfling to binding and have no doubt the glue softens during bending but sets again during cooling. No problem because the set is taped tightly together. I just use masking tape,a bit of work to clean up but works nicely.

Tom

__________________

A person who has never made a mistake has never made anything Last edited by Tom West; 02-15-2012 at 11:09 AM. |

|

#14

|

|||

|

|||

|

so far everyone who's responded uses the tried and true method of taping alternating strips together and sticking them in the bender.

seems like i need to be more aware of grain run out, and try to bring the thickness down a little bit. thing is i like the look of a thick binding strip. i'm still curious how somogyi would go about bending the purfling strips separately? one huge advantage he has i doing this, is that he can cut his binding strips out of one large pre bent piece, just like a side would be, while clamped in a domed mold to match the radius of his top and back. he clamps the side in the mold, then uses an upright dremel or laminate trimmer with a slotting cutter blade on it, and moves around the mold. the result is that the binding strip with have the appropriate radius as it moves from end block to neck block. since i use a 25' top and 15' radius back, this would help tremendously in getting a good fit and not having to fight the binding strip while it tries to bend in 4 directions as i tape it in place. any thoughts on this? i'm guessing he just tapes the alternating purfling strips together and bend's them the same way you would the binding. anyone had success with this method? ryan gerber www.facebook.com/gerberguitars |

|

#15

|

|||

|

|||

|

Quote:

|