|

|

#16

|

|||

|

|||

|

Nope sure wasn't. Tooth set was uneven too so it was a fight to keep it cutting straight as well. But you're missing the point of my story. If you have access to proper tooling, whether that be some piece of equipment or just a well set up hand saw, that can affect what materials can be considered 'economical' and should be considered when jumping into a project.

|

|

#17

|

|||

|

|||

|

The more tools you have, the cheaper the build becomes, the less tools you have the more expensive, the reason for this, is because you are relying on others to do the job and in doing so incorporate their costs.

Example, I can make a guitar neck / fretboard / trussrod and frets for under $8 material costs, you would pay for example stewmac or someone like that $195 for an acoustic neck. No matter what part of a guitar, more tools = cheaper build costs Steve

__________________

Cole Clark Fat Lady Gretsch Electromatic Martin CEO7 Maton Messiah Taylor 814CE |

|

#18

|

|||

|

|||

|

Your shop equipped with the hand tools used by Martin in 1870 would make the guitar cheaper to build than your shop equipped with the ones they use today. All depends on how many you are going to build - the more you build the faster you can work with the power stuff.

Ed |

|

#19

|

|||

|

|||

|

Quote:

With that guitar neck example, I can cut out all the pieces for my laminated neck design in less than an hour on the bandsaw. I can do all those same cuts just as accurately by hand, but it takes over four hours. Now, if you're going to buy premade parts instead of spending hours with hand tools making those parts, Steve is exactly right.

__________________

Rodger Knox, PE 1917 Martin 0-28 1956 Gibson J-50 et al |

|

#20

|

|||

|

|||

|

Quote:

Focus more on learning the theory behind different building methods and construction types. Use that knowledge to build your own jigs as you go, but really you need to focus on getting a workshop put together. That’s more than tools though. You need to think of humidity, storage and having an easily accessible work area. It isn’t something you can do on your kitchen table unless your wife is the craftsy type and doesn’t mind clutter. As for tools you’ll needs clamps, chisels and a couple of good planes. Learn how to sharpen them. You may bleed less; blunt blades snag on the work and inexperienced hands usually get in the way. Get starter tools from Harbor Freight or an outlet mall. Don’t get tempted when you go to a big box store or Stewart MacDonald. They’re just overpriced. For materials, buy up a lot of good quality 3/4” birch plywood to make jigs. I wouldn’t be looking for tonewoods inasmuch as figuring out how all the pieces fit together. I’d start by making a mold then buy a kit. I’d recommend a rosewood/Sitka guitar with a mahogany neck with a dovetail joint. My first build was a scratch mahogany/western red cedar build with a laminated neck with an MT neck using barrel bolts. There were lots of pitfalls. The first set of mahogany sides split and cupped (the side curled along the grain  build #2 is rosewood and much more pliable that bent like butter and has held its shape. Build #1’s cedar top was also easily marred; #2 is Carpathian and less prone to chipping. The barrel bolts on the neck joint on my first build greatly weakened the tenon structurally; #2 will have threaded inserts; #3 will be a kit with a dovetail joint. build #2 is rosewood and much more pliable that bent like butter and has held its shape. Build #1’s cedar top was also easily marred; #2 is Carpathian and less prone to chipping. The barrel bolts on the neck joint on my first build greatly weakened the tenon structurally; #2 will have threaded inserts; #3 will be a kit with a dovetail joint. If I had to do it all over again I’d have bought a D-28 kit from John Hall of Blues Creek Guitars. It would have probably only set me back $1000 and taken a long t less than the four years that it stretched out to be.

__________________

(2006) Larrivee OM-03R, (2009) Martin D-16GT, (1998) Fender Am Std Ash Stratocaster, (2013) McKnight McUke, (1989) Kramer Striker ST600, a couple of DIY builds (2013, 2023) |

|

#21

|

|||

|

|||

|

I might suggest not buying edge tools from Horror Freight - they have good clamps, but anything with an edge is less than optimal. The stuff you buy at Home Despot and Blowes is home duty - you want good cutting edge tools so that they are easy to sharpen, hold their edge, fun to use, and are balanced. Let me suggest a vintage plane in very good shape might be $25 (you could pay more for a better looking version of the same tool) and $10 apiece for good vintage chisels.

And all of my molds (I have accumulated 6 at this point) are A/C plywood with scrap 2X material spacers between, one I have used 4 times, and they are all in fine shape ready to go again. You will want to upgrade at some point if you decide to make a living at this, but for us amateur (French for "lover") builders, just getting going is what is needed. Ed |

|

#22

|

|||

|

|||

|

Example, I can make a guitar neck / fretboard / trussrod and frets for under $8 material costs, you would pay for example stewmac or someone like that $195 for an acoustic neck.

Good lord, where are you shopping? Or did you forget a zero? |

|

#23

|

|||

|

|||

|

I’d agree with that to an extent. I bought Blue Marples chisels from Rockler but the bench plane that I use for shooting, the little block plane that I use for the headstock and planing the kerfing and the little finger plane that I use for planing the angle on the sides of my braces are serviceable. They all required a bit of setup (flattening the soles, getting the blades Scary Sharp) but are adequate for a small hobby builder.

__________________

(2006) Larrivee OM-03R, (2009) Martin D-16GT, (1998) Fender Am Std Ash Stratocaster, (2013) McKnight McUke, (1989) Kramer Striker ST600, a couple of DIY builds (2013, 2023) |

|

#24

|

|||

|

|||

|

Quote:

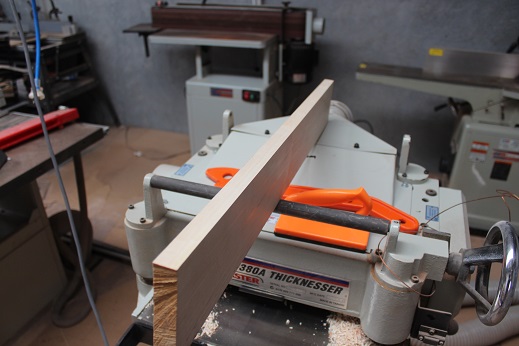

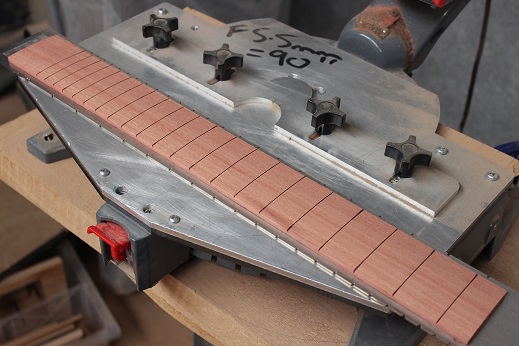

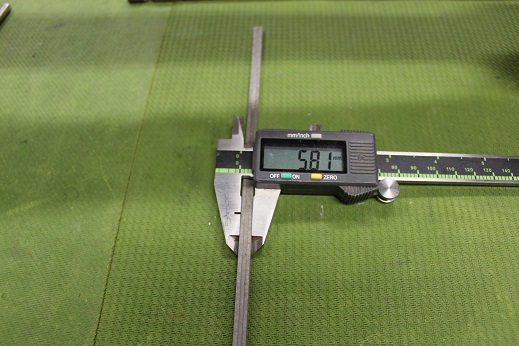

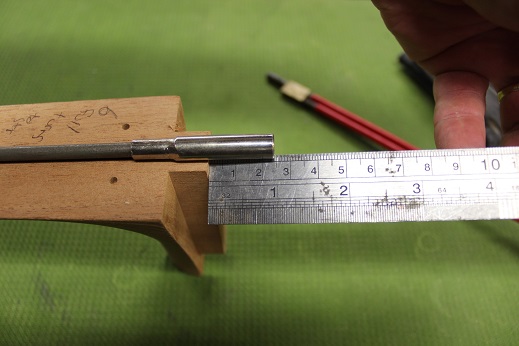

Gone are the days it appears where most luthiers take a raw product and create something from it, with the advent of companies like stewmac online ordering system or warmoth, a person can place an order for a fretboard of a specific species, thicknessed profile shaped/fret slotted and ready for fitment, or even completed necks. Back to raw products Example, this maple plank of wood, cost me $3 from the lumber yard, admittedly, I buy 100 at a time. I have walk through tutes on making all this stuff.   This is what you get after dressing the wood in house, that is, faced and cut on a jointer, then a thicknesser, then a table saw. This is what others pay $30 for from suppliers such as stewmac, lmii and so forth.  Fretboard blank $2  Shaped and turned into a fretboard, what people pay 35 dollars for, but we used, thicknesser, jointer, tablesaw, belt sander for radius, slotting saw for fret slots  I make my own truss rods $0.90, but again, lathe for turning parts, tig welder for assembly    I dont make my own fretwire, have tried but. $1.20 two lengths Fret markers I cut from scrap pearl off cuts, but maybe it has a 30c value  Steve

__________________

Cole Clark Fat Lady Gretsch Electromatic Martin CEO7 Maton Messiah Taylor 814CE Last edited by mirwa; 09-17-2018 at 02:00 AM. |

|

#25

|

|||

|

|||

|

I would keep an eye on Craigslist. I recently hit the motherlode with a StewMac 000 kit, clamps, mold, and various other tools plus a WhiteGate bench all for $350.00. I would say that is unusual, and lucky for me, but I also got a US Guitar Kit by trading 4 microphones, and an XLR cable from a guy. This was not quite as good as my last deal as I did have to buy a few extras that were not with the kit, but it was a decent deal. I am currently in the process of building this guitar now. I also had some expert help from Redir on the forum as he graciously helped me figure out a neck angle that was troubling me. Check out your local area for any luthiers who might be able to help you. I have found answers on this forum from all of the excellent contributors who offer their expertise for free, and seem to be happy to help aspiring builders. Good luck with your build, and I think you can get it done, and have a nice sounding guitar.

Clifford

__________________

Recording King RD-318 Bedell TBAC-28-SB Jeff "Skunk" Baxter |

|

#26

|

|||

|

|||

|

There is no way I would be getting maple for $3 a blank or fretboards for $2 even if I bought material for 100 where I live. Only one retailer of raw wood other than Home Depot or the like and their selection is oak, maple and fir, not cheap either. I will say that I did get a part box of flooring that I sawed into fretboards and bridges which came in under $2 but that was a case of being in the right place at the right time as they were going to throw it out.

I have built my own truss rod on my first build, have a welder also. If I were building a lot of guitars it might be worth setting up with jigs and processes to work materials from the raw state. I do have a planer, jointer, table saw, bandsaw, drum sander (underpowered), and I have worked raw wood to shape, even from a log. I spent some time figuring out how to make viable guitars using 2"x4"s as necks and resawed pine boards for the body in order to make giveaway guitars for younger kids. With some cheap tuners and fretwire bought online a guitar can come in under $35. But then I realized a kid might knock it around more than I do and a softwood guitar might not last all that long. Next cheapest might be to make the guitar out of maple, too busy to try it for now and I really should rebuild the bandsaw before doing any more resawing. Darn, I feel like going downstairs and seeing what maple I have for resawing.

__________________

Fred |

|

#27

|

|||

|

|||

|

Lumber yards are your friend

, if you have the tools to work the wood. , if you have the tools to work the wood. Home depot for example, have already done a mark up for having had it dressed, for having it shipped to them, for displaying it on the shelf and paying employees to sell the product. Steve

__________________

Cole Clark Fat Lady Gretsch Electromatic Martin CEO7 Maton Messiah Taylor 814CE |

|

#28

|

|||

|

|||

|

I'm working on an oak parlor guitar that the back and sides were resawn from a 30" long 1x6 from HD. I found quite a few pieces of nice curly maple at HD over the years, and one store near me stocks walnut. It is a little more expensive than a lumber yard, and the selection is limited, but it's a viable alternative if no lumber yards are within easy access.

__________________

Rodger Knox, PE 1917 Martin 0-28 1956 Gibson J-50 et al |

|

#29

|

|||

|

|||

|

Roger

I was just going to mention that the 2 Home Despots and the 2 Blowes near me have maple, and a couple of times a year I run across a curly maple board in the mix at the same price. Haven't built an instrument with it, but I have built 2 pieces of furniture. Ed |

|

#30

|

|||

|

|||

|

I bought milled wood from a big box store also, hate paying top price. But the piece of wood was nicely curled and I cut it for binding so I accepted the cost. The problem with our local lumberyard is they know you don't have anywhere else to get anything different than the box stores so they charge top dollar.

__________________

Fred |