|

|

#1

|

|||

|

|||

|

Little chuffed, I occasionally get to do some odd wood stuff.

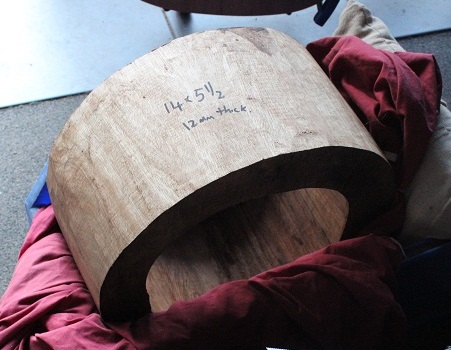

Whilst not a guitar build or repair. I made a Jarrah shell for Brady Drums a while back, he finished the job off and it was being sold to Charlie Watts, but ended up going to Fleetwood Macs private collection. As given to me, I machined and turned this into a 12mm thick shell  After Brady Drums put the hardware on.  Here is one I did from start to finish for another drummer, solid wood Start  What I gave him - Finished

__________________

Cole Clark Fat Lady Gretsch Electromatic Martin CEO7 Maton Messiah Taylor 814CE |

|

#2

|

|||

|

|||

|

Most excellent!

As a drummer myself, i've already decided somewhere along the line i'll make myself a snare or 2, but I haven't got round to it yet mostly because I haven't worked out how i'll machine the insides, expecially when I want to do a 12" snare, I don't think even my palm router will fit inside without it being on a mount. One day though.....

__________________

David |

|

#3

|

|||

|

|||

|

Yes I was chuffed.

Segmented snares are better for machining, they are more dimensionally stable. These ones were scary to machine becuase they are a single piece of wood being bored and hollowed out. Clearly the best way to machine them is on a lathe, but if you make the segments neatly, you could clean the inside up quickly with a bobbin sander or sandpaper wrapped around a pipe turned vee a drill. The more segments, the closer you can get the insides to almost perfect before any sanding Steve

__________________

Cole Clark Fat Lady Gretsch Electromatic Martin CEO7 Maton Messiah Taylor 814CE |

|

#4

|

|||

|

|||

|

That's very cool. I had no idea that the shells were that thick.

|

|

#5

|

|||

|

|||

|

Sorry, that is pre machining almost an inch and a half thick, after machining, I take it down to about 1/2 inch.

Here’s a better photo, apologies for confusion

__________________

Cole Clark Fat Lady Gretsch Electromatic Martin CEO7 Maton Messiah Taylor 814CE Last edited by mirwa; 06-07-2018 at 07:58 AM. |

|

#6

|

|||

|

|||

|

Oh no I got that, you said 12mm. I didn't realize they were even that thick.

|

|

#7

|

|||

|

|||

|

Nice!

...... |

|

#8

|

|||

|

|||

|

Quote:

My charge for making the shell from a lump of wood was 500, so good money, but very very long job as you have to keep accomodating the natural twist of wood as you machine it away and machine it over a two week period, the wood is dried and stored away for 6 years to start with before I got them. Normal drums are about 3mm wall thickness. Realistically its just like a guitar in we are working with wood, working with grain / twist / cracking / finishing etc. Steve

__________________

Cole Clark Fat Lady Gretsch Electromatic Martin CEO7 Maton Messiah Taylor 814CE |

|

#9

|

|||

|

|||

|

Quote:

|

|

#10

|

|||

|

|||

|

Missed this when you posted originally. Very cool and very nice looking drums!

|