|

|

#1

|

|||

|

|||

|

Hallo

As a hobby me and a friend of mine construct instruments. We are thinking of buying a cheap Chinese laser as cheap as possible for inlays (1,5 - 2 mm wood). Has anybody used such laser before, if yes which model and if pleased with the outcome. Has anybody used the ebay lasers and especially K40 which is very cheap? Thank you !!! |

|

#2

|

|||

|

|||

|

It's not the machine you need, it is "the what you are going to do with it".

check the experience on the cnczone.com, it is where the laser expertise is. I have seen terrible laser work which always needs hand work. There are no freebies to doing correct inlays. Try doing the inlay design first, then test burn it into junk wood. Rent someone's machine and use your data. I had to go thru two laser amateurs with cheap machines before i called my friend with 30years experience and a 15k machine. correct parts first time out. We can assist ... https://drive.google.com/open?id=1RD...znNuTVnzBEDawN

__________________

Been doin this, way too long..... |

|

#3

|

|||

|

|||

|

Thank you for the response.

I am also worried that the cut quality will be bad. I have tried once to cut in an american laser of a shop and the quality was perfect. Unfortunately in Greece there are not any laser for rent, and for this reason i am asking for the opinion of someone who has used lasers for such work. The only chinese laser i have tried in Greece is the Bodor and i was satisfied with the outcone. However it costs 4000E. I haven' t tried the ebay lasers (1000-2000E) since they are not available here. I will visit the site you suggested in case someone has experience on cheap lasers. Thanks again. |

|

#4

|

|||

|

|||

|

If itís a hobby, couldnít you do it with a small pantograph router? Save a whole lotta money, which could be put into materials or tools which would actually make better instruments -

__________________

More than a few Santa Cruzís, a few Sexauers, a Patterson, a Larrivee, a Cumpiano, and a Klepper!! |

|

#5

|

|||

|

|||

|

Hallo. Thank you for the response.

I have used the cnc of a friend but it leaves gap between the inlays equal to the width of the bit (there is the option one of the two wood to be slightly larger so as to fit but i would like to avoid it). Besides the inlays are so small that cnc may break them. In general i think that with the laser it will be easier and more detailed. Thanks again! |

|

#6

|

|||

|

|||

|

Quote:

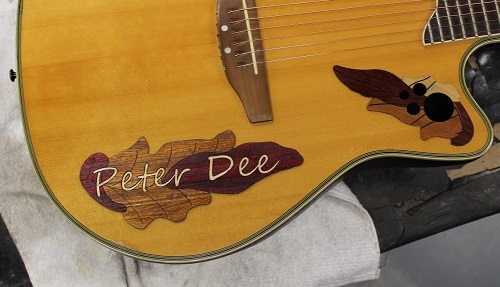

The only thing you cannot do is cut pearl with a standard co2 laser, there are people who will say you can, but the pearl sheet is the thickness of a piece of paper which is pretty well useless. Here is an example, all laser cut  Steve

__________________

Cole Clark Fat Lady Gretsch Electromatic Martin CEO7 Maton Messiah Taylor 814CE |

|

#7

|

|||

|

|||

|

Another example,

This one I used the laser to pocket the headstock of the PRS, and then I Cnc machined the mother of pearl, it was a press fit

__________________

Cole Clark Fat Lady Gretsch Electromatic Martin CEO7 Maton Messiah Taylor 814CE |

|

#8

|

|||

|

|||

|

Yassou George,

There is cnc software that compensates for the cutter size, and adjusts the size of the inlay to match...such as that from Vectric in the UK. It still takes skill with the cnc router or laser to achieve a tight fit.

__________________

Angie |

|

#9

|

|||

|

|||

|

If you have info on good, inexpensive software that will do 2.5D and generate Gcode, Iíd love to hear about it. Ideally something simple that will run on iPad or Mac - I would be interested in doing inlay, but I really want to mill printing plates -

__________________

More than a few Santa Cruzís, a few Sexauers, a Patterson, a Larrivee, a Cumpiano, and a Klepper!! |

|

#10

|

|||

|

|||

|

Vectric in the UK produces Aspire CNC software. It runs on a PC, or a Mac in PC emulation mode. It will do 2.5 d, inlay, etc. it is everything you asked about except it is not cheap.

__________________

Angie |

|

#11

|

|||

|

|||

|

Aspire is around 2000 plus dollars, I have cut3d and vcarve from the same company, both are great programs, cut3d cost me around 500 usd, I think and vcarve was just shy of a thousand or so when I bought it.

The two examples above were both done in vcarve. Steve

__________________

Cole Clark Fat Lady Gretsch Electromatic Martin CEO7 Maton Messiah Taylor 814CE |

|

#12

|

|||

|

|||

|

Well, I only have a grand tied up in my mill, and itís just been upgraded with a very cool controller made by a company called Buildbotics - itís a small family business about a block away from Bruceís shop in Petaluma. Not interested in becoming a machine programmer - hoping to find software that can do some very simple things for very simple money while I figure out if this machine has a place in my shop. Looking at Inkscape, which has a Gcode plug-in, and Buildbotics has an simulator called Camotics, which should be able to output code shortly. But Iíd rather put time and energy into practicing my scales and flat picking than into learning to code - 😎

__________________

More than a few Santa Cruzís, a few Sexauers, a Patterson, a Larrivee, a Cumpiano, and a Klepper!! |

|

#13

|

|||

|

|||

|

For laser engraving, you should be able to "print" directly from programs like Inkscape and Corel Draw without the need for the intermediary step of generating G code. That one doesn't need G code for most basic cutting/engraving is one of the things that makes lasers the most accessible of CNC machinery.

|

|

#14

|

|||

|

|||

|

Quote:

__________________

Been doin this, way too long..... |