Finished the side bending machine. Light bulb style. 2 150 watt bulbs and 1 200 watt bulb.

Form building with my newly constructed router table. I built that too since I last posted here. It was handy for several tasks I've had to do over the last couple weeks.

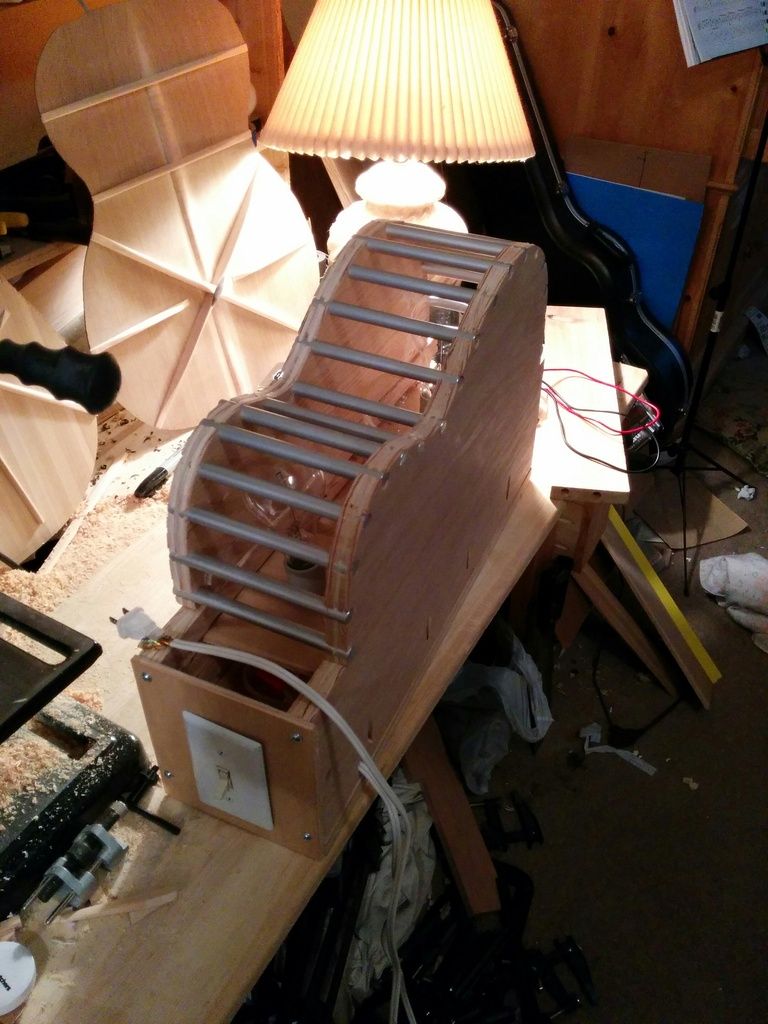

The form with the aluminum bars in place.

The completed bending machine.

The first side cooling in the machine. Crazy how hot that thing got from just a couple light bulbs. It was hot to the touch through a pair of leather gloves. I had thicknessed the sides to just under .1 inches.

Took a bit longer than I expected, but no matter. Feels like a colossal hurdle has been passed, having successfully bent a piece of wood. Now I just have to thickness and bend the other one. After that, on to building the mold that will be the side's home during block and kerfed lining installation.

I'd like to hear some commentary on the way I went about bending the wood. I would spritz a little water on, then wait a couple minutes for it to heat up and begin to evaporate, the steam being what I believe is heating and allowing the wood fibers to relax. Then I would crank down the nuts on the eye bolts a couple turns. Once the wood was dry, I would crank another time or two, and then slightly re-wet. Should I wet the wood multiple times? Or just once at the beginning? This was successful, but I wonder if I used too much water. I suppose it doesn't much matter as long as it worked.

Sigh. Dreams are 1 small step closer.