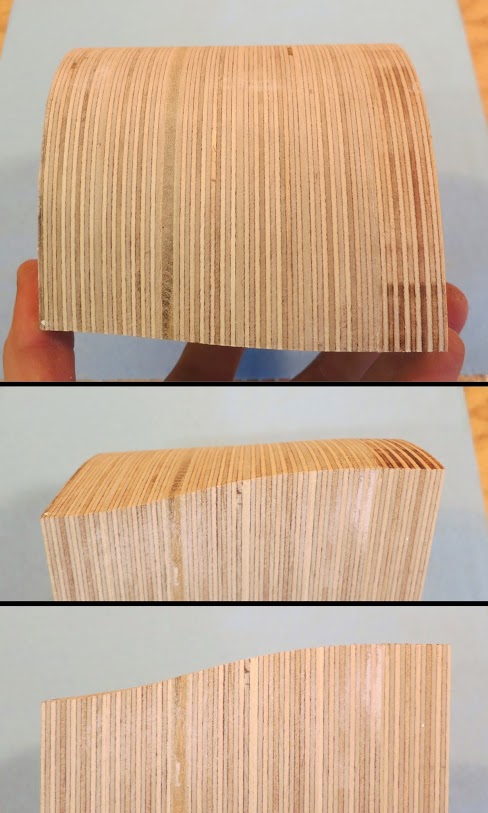

Made some more progress on the cutaway these past few days. For those that might be uncertain what I mean when I say flush to the heel, here's an example of one I made a few years back...

The obvious difference between this and most cutaways is that I maintain the same heel shape with a perfectly smooth transition to the side. Some of the main challenges in this style of cutaway are getting the wood to bend in more ways than one (follow the curve of the sides and of the heel at the same time) and keeping everything perfectly lined up and on center. In order to achieve this, I made a bending/lamination mold for the cutaway section...

As you can see, it starts flat and perpendicular to the top/back. As it approaches the fingerboard it starts to angle but still remain flat. Once it reaches the end-block, it starts to transition from flat into the final heel shape. Since it is such an amorphous shape, this all has to be carved by hand.

Now comes the challenge of laminating! For the flat sections, I use the same brace and bolt system that I use to laminate my sides. However, for the curvy heel section, I need to make a caul that is an exact fit (plus the thickness of the sides) in order to get perfectly fit lamination. So, plaster of paris to the rescue!

And here's a shot of the cutaway being laminated with the plaster mold and brace/bolt system...

That's it for now. Next up is carving the block!

Mike