We typically hear the top is where most of the sound comes from and is the largest influencer in the sound from any given guitar. Next in line is the back and sides which sometimes are said to be the seasoning for the sound.

Here is another way to look at this: Yes, I agree the soundboard is the strongest influencer but the second is the top bracing, not the back and sides. Now, I realize the top in the first statement is usually thought of as both the soundboard and the bracing but, I'm saying that even if you were to consider the bracing separately it would have more influence on the sound than the back and sides.

So braces are important. I shake my head when I hear a builder say, "Braces are an unfortunate necessity to keep the guitar top from caving in". Braces are very much more than that. They are one of the chief ways that a builder can manipulate the sound characteristics and response of a guitar and hopefully optimize the materials and goals of an instrument.

The first guitar I made, like many builders, was right out of the Cumpiano and Natelson book; Guitarmaking Tradition and Technology. Chapter 7 called "Soundboard Bracing" had a section called "Procedure: Preparing The Brace Blanks". I read it and it made sense to me and I followed along ever since. I just thought that was how it was done and incorporated that into how I always did it. I was disappointed to find my assumption of this being common practice was wrong.

So what is this procedure? It's really all about riven wood or splitting out your blanks so the braces are perfectly quartered in one plain and have absolutely no run out in the other. A perfectly straight grained brace is easier to carve, is more homogenous in it's stiffness along it's length, it's less likely to crack, and most importantly, it is up to 30% stiffer than a poorly prepared brace from the same board. So that means, you can make that brace a lot lighter to do the same job, which means what little resource of power you have from the strings isn't wasted on throwing around weight you don't need. This makes for a more responsive guitar in both response quickness and volume.

It's not too hard to split out the wood but. you do have to have good straight grained wood to start with. That's not too much to ask considering how much money and time we spend trying to pick out the less important back and side wood set. I use a bamboo splitting froe which is typically used for hand made bamboo fly rods (another application that obviously needs to be strong).

Lets' take a historical view of this. Here is a picture of the most famous piece of riven wood in the world. It is on display in the Smithsonian Museum:

Seems appropriate to show this because today is an election day and this was a campaign prop from the 1800's. Abraham Lincoln's campaign manager went back to Illinois to get a piece of one of the split fence rails that Abraham rived to use in his campaign. You see saw mills were spreading across the country and like any new technology there were pluses and minuses. The easiest way to make a board used to be to split it out of a log. Now saw mills could cut them much faster. The split boards were of much better quality, they stayed straight, were stronger, and lasted longer, but, were more work. These were the exact qualities Abraham Lincoln wanted to emulate in his campaign. It's still valued today, as celebrated on the back of a 2009 penny:

Sawmills, table saws, and bandsaws were a great advancement in technology and manufacture and saws are often used to make brace blanks. When asked why something as important as braces are being sawn instead of split the answer usually is "Saws are faster and there is a lot less waste."

You have to ask yourself, do you want your braces made out of waste wood?

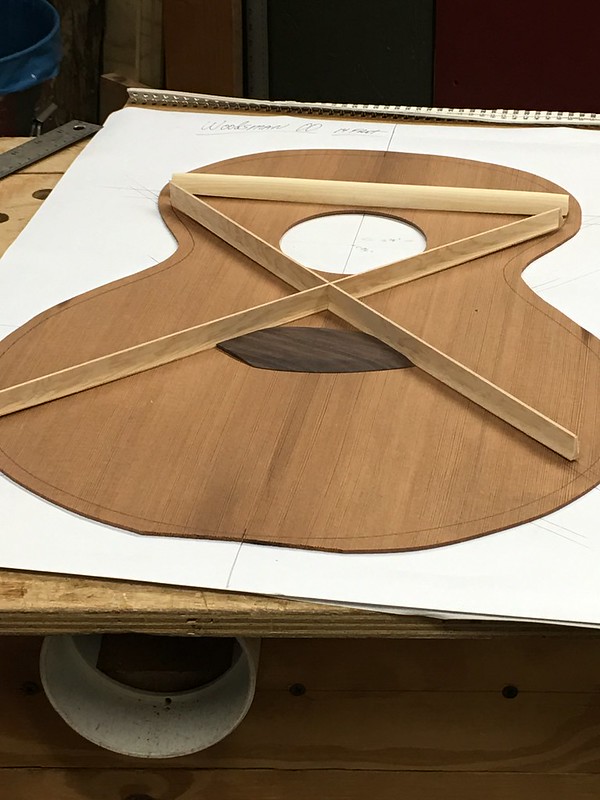

I started bracing the top today with riven wood:

Thanks for following along!

Mark