|

|

#1

|

|||

|

|||

|

I was in the market for a smaller guitar and by researching on this forum I learned about Go Guitars by Sam Radding. I became intrigued with the idea of having this famed American Dream guitar shop luthier and Bob Taylor's early mentor build me a custom guitar. Another bonus was that his shop is very near where I live and Sam is very accommodating in allowing me to stop by to observe and photograph my guitar's progress.

Watching Sam as he works it's clear guitar building comes very natural to him. Sam uses jigs when things need to be exact but often trusts his instincts to know when parts are how he wants them. I plan to put one of those photo books together showing the many stages in the building of my guitar. I thought I'd share with the forum some of the photos as it goes along. Sam uses many of his own unique methods and techniques that he has found effective over a lifetime of guitar building. Here is a description and initial photos of Sam turning raw materials into something very special just for me. More to follow: Back and Sides: Cocobolo Top: Sitka Spruce Fingerboard/Bridge: Ebony Neck: Sapele 1 3/4 in. Binding: Fiddleback Maple Rosette: Cocobolo Upper Bout: 11 1/4 in. Lower Bout: 14 5/8 in. Length: 19 1/8 in. Depth: 4 1/8 in.

|

|

#2

|

|||

|

|||

|

The iron for bending the cocobolo brings me to ask the question, was the waist bent on a pipe and the bouts ironed to shape? I have used an iron to flatten wood, never thought to use it to initially shape the wood. That wood is eye candy.

|

|

#3

|

|||

|

|||

|

Looking forward to seeing the end product. Very cool! Love that back wood.

__________________

Susie Taylors: 914 K24ce 414 GSMeK+ Pono Guileles: Mango Baritone Deluxe Mahogany Baritone Have been finger-pickin' guitar since 1973! Love my mountain dulcimers too! (7 Mountain Dulcimers) |

|

#4

|

|||

|

|||

|

Quote:

|

|

#5

|

|||

|

|||

|

Progress continues with the creation of the head and tail blocks and the back's center strip.

|

|

#6

|

|||

|

|||

|

I picked up another Go Guitar this morning, Christmas gift. Sam builds incredible guitars, some of the nicest parlor guitars that I've ever seen.

I'm really looking forward to seeing more photos as this build progresses. |

|

#7

|

|||

|

|||

|

Here is a two minute YouTube of Sam working on the Honduran mahogany kerfing for the guitar. It includes still photos and some video of his interesting kerf cutting contraption. This jig needs to be seen in action to be fully appreciated.

https://www.youtube.com/watch?v=h00ezkNHh5g |

|

#8

|

|||

|

|||

|

The back is gorgeous.

__________________

Susie Taylors: 914 K24ce 414 GSMeK+ Pono Guileles: Mango Baritone Deluxe Mahogany Baritone Have been finger-pickin' guitar since 1973! Love my mountain dulcimers too! (7 Mountain Dulcimers) |

|

#9

|

|||

|

|||

|

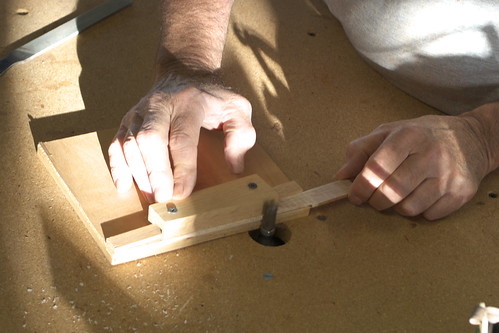

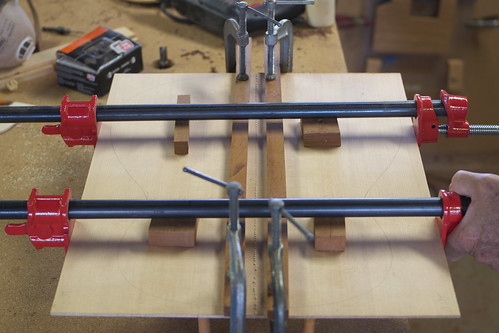

HAPPY NEW YEAR!! I hope I'm not getting too carried away with so many pictures but all the steps in creating a guitar are all so fascinating to me. These cover creating the back's bracing.

Routing the radius to the back braces using template.  Jig for locating brace position and applying epoxy to both surfaces.   Clamps forcing the back to the brace's radius. Hand shaping the top of each brace.   Brace sanding jig. Shaping the ends of each brace.   Alignment of center strip.  Clamping the glued center strip. Completed back bracing.

|

|

#10

|

|||

|

|||

|

A few more side preparations:

|

|

#11

|

|||

|

|||

|

Attaching the Back and Sides:

|

|

#12

|

|||

|

|||

|

Looking good! Can't wait to see the final product.

|

|

#13

|

|||

|

|||

|

A big step forward...selecting the top. I've been reading the forum threads regarding what makes a "good" top and it finally came time to pick one. I concluded a good top should be stiff with fine straight grain and even color. Silking can be a good thing and bearclaw is not a bad thing. Sam laid out a half dozen tops he was happy with for me to choose from. The top chosen has these traits including an interesting bearclaw symmetrically spread across the top.

|

|

#14

|

|||

|

|||

|

Looking great!!!

__________________

Susie Taylors: 914 K24ce 414 GSMeK+ Pono Guileles: Mango Baritone Deluxe Mahogany Baritone Have been finger-pickin' guitar since 1973! Love my mountain dulcimers too! (7 Mountain Dulcimers) |

|

#15

|

|||

|

|||

|

Coda,

I'm loving this thread! Pictures are superb. I also have a guitar built by Sam a little Go Grande Mahogany travel guitar that I adore. I found Sam very easy to work with and I appreciated the fact that he let me do some little custom things to it. The day I got my Go, it completely replaced the travel guitar I had been using. Great guitar for the money. Congratulations on your decision to use Sam and I can't wait to see the finished product.

|