|

|

#16

|

|||

|

|||

|

Soldering was my stock in trade for a good part of my working life and is a skill that, once learned, is invaluable. Learn how to do it properly, and you'll never have problems. The critical bit here is properly. Otherwise you end up with potential dry joints that might come back to bite you down the track in the form of noise and open circuits, some of which only occur after the machine has warmed up. Good technique instructions.

__________________

Maton CE60D Ibanez Blazer Washburn Taurus T25NMK |

|

#17

|

||||

|

||||

|

I've been soldering since I was a kid and have done lots of repairs on my gear over the years. Funny thing, though: As I've ended up with some really beautiful instruments, I've begun to dislike working on my instruments. It's the finishes: I've gotten scared of slipping and damaging the finishes. I adjust truss rods and intonate instruments and so forth but would just as soon leave replacing pots on an expensive guitar to my excellent luthier. It's even more funny because I'm not squeamish about working on my amps.

Bob

__________________

"It is said, 'Go not to the elves for counsel for they will say both no and yes.' " Frodo Baggins to Gildor Inglorion, The Fellowship of the Ring THE MUSICIAN'S ROOM (my website) |

|

#18

|

|||

|

|||

|

Quote:

1. It can reach a much hotter max temperature than my old iron. That's invaluable if you have a tricky soldering job with a large mass of metal which likes to suck all the heat away from the joint. The hotter the iron, the better the chance you have to zap the joint before all the heat is lost. In general, the task is to flash-heat the wires being soldered, and the solder itself, for the minimum amount of time necessary to create a good joint. If you're too delicate you'll get dry solder joints which may not conduct properly or, if they do pass a continuity test, may have unusually high capacitance. On the other hand, if you're too profligate with the heat, you risk damaging sensitive parts or even melting through wire insulation. It's a balance. 2. A soldering station will increase the power when it detects a drop in temperature. This helps to maintain temperature much better than a constant power iron which cannot try to compensate when heat is sucked out of the tip. 3. Variable power means that you can reduce wear on the tips by turning the iron down to a low temp while you prepare wires etc for the next joint (oxidation adds an insulating layer of rust which stops the tip getting fully hot and oxidation rates are worse the hotter the iron). When you're ready, the iron will get back up to working temperature quickly once you dial it in. 4. I can get a range of tips to fit my solder station for different types of soldering job: fine points for some of the fragile components in guitar pedals, medium "screwdriver" heads for general use, and large lumps of metal for difficult jobs where you need a big thermal inertia - such as soldering a safety ground to the chassis of a tube amp. A soldering station isn't essential but if you can find one at a good price it's definitely worth considering. It should improve your chances of producing good joints. Also look at eutectic solder

Last edited by moon; 02-15-2017 at 09:46 PM. |

|

#19

|

|||

|

|||

|

I hate soldering, but all my longest-serving guitar leads are those I soldered myself.

|

|

#20

|

|||

|

|||

|

Always have. I hadn't known there were people who would do that for you, so it was a skill I picked up along with other elements of instrument and gear maintainence.

|

|

#21

|

|||

|

|||

|

Quote:

Wow. What do the numbers mean on the board? |

|

#22

|

|||

|

|||

|

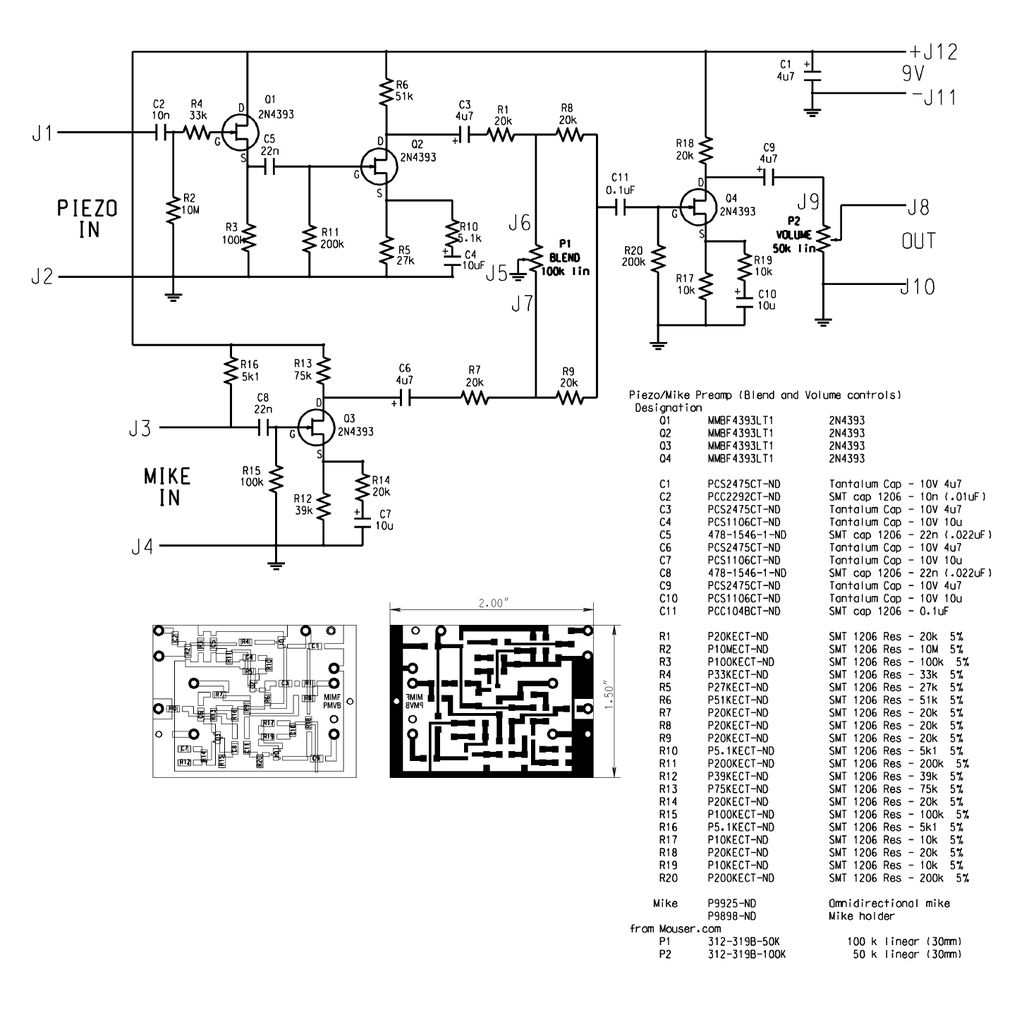

Those are the ID codes for the components. There are transistors, capacitors, and resistors. That's actually pretty funny, they are easy to read in the photo. In person, they're too small for me to read, so I had to keep them in the original packaging until they were soldered to the board. They are SMT 1206 components.

Here's the schematic with all the component data:

__________________

Rodger Knox, PE 1917 Martin 0-28 1956 Gibson J-50 et al Last edited by Rodger Knox; 02-16-2017 at 03:26 PM. |

|

#23

|

|||

|

|||

|

Yes. I've got an 85W Hakko digital station and a range of tips for it. If you're going to solder to pot casings for grounding, you need plenty of power to get the joint up to temp quickly without overheating the whole pot and destroying the internals. Plenty of reserve power and a fat chisel tip are perfect for that.

Sent from my SM-G920V using Tapatalk

__________________

"You don't have to be great to start, but you have to start to be great." -Zig Ziglar Acoustics 2013 Guild F30 Standard 2012 Yamaha LL16 2007 Seagull S12 1991 Yairi DY 50 Electrics Epiphone Les Paul Standard Fender Am. Standard Telecaster Gibson ES-335 Gibson Firebird |

|

#24

|

|||

|

|||

|

Hey Rodger, I thought it was probably codes for the components but wasn't sure.

Quote:

|

|

#25

|

|||

|

|||

|

I've been soldering since the 60s and have scars to prove it.

__________________

I don't have a bunch of guitars because they all sound just like me.  1984 Carvin LB-40 bass 1986 Carvin DC-125 two humbucker 1996 Taylor 412 La Patrie Concert 2012 American Standard Telecaster 1981 Carvin DC 100 Harley Benton LP JR DC Bushman Delta Frost & Suzuki harmonicas Artley flute Six-plus decade old vocal apparatus |

|

#26

|

|||

|

|||

|

Quote:

__________________

----------------------------------- Creator of The Parlando Project Guitars: 20th Century Seagull S6-12, S6 Folk, Seagull M6; '00 Guild JF30-12, '01 Martin 00-15, '16 Martin 000-17, '07 Parkwood PW510, Epiphone Biscuit resonator, Merlin Dulcimer, and various electric guitars, basses.... |

|

#27

|

|||

|

|||

|

I built a few electronic kits starting not quite 50 years ago and then a lot more stuff. So my soldering is OK. Build a kit or two and you'll get a lot of practice. Don't use a gun for most purposes: use a decent iron. I have an old Ungar - not as good as something like the Hakko station, but good enough.

Soldering is not paste-spreading. Heat the pieces enough so that they are hot enough to melt the solder. Some helpful guides: https://learn.adafruit.com/adafruit-...lent-soldering http://ljkrakauer.com/LJK/80s90s/heathsolder.htm |

|

#28

|

|||

|

|||

|

I do my own soldering.

__________________

(insert famous quote here) |

|

#29

|

|||

|

|||

|

I do my own soldering for a long time now - I actually learned when I went to school to be an audio engineer. A very large part of the curriculum was soldering and I remember making a pretty decent sounding preamp. Wish I still had that!

|