|

|

#1

|

|||

|

|||

|

Another question I've been pondering as I tackle another build. Are there strategies or tricks to make the glue lines for a stacked heel, or a headstock scarf joint less conspicuous? Even when the dry fit is perfect, seems I can't carve the neck without having the line between the heel and neck, or the scarf joint, be pretty visible...

It doesn't look terrible, but it is a bit jarring.. thanks for any tips! |

|

#2

|

|||

|

|||

|

I tried to imagine the grain where I was going to carve and hopefully the line up the blocks to get the grain to match. Not too bad in a couple of cases. For the scarf joint there is always a head plate to the rescue.

|

|

#3

|

|||

|

|||

|

It's all about placement. Taper the neck shaft thickness as close to final as possible before you glue the headstock/heel onto it. I do 3/4" thick at the 12th fret and 5/8" at the nut, though I do usually thin it a little more during final carving. Better safe than sorry.

The heel will always be somewhat conspicuous, but the headstock glue line can be almost invisible except from the side. I use a handstop lip that curves up sharply right at the glue line, and then the whole back of the headstock is pristine long grain, even better looking than the short grain surface of a one-piece neck:  Oh, and for heels, an actual stack almost always looks ugly. But if you can get a single block for it, or laminate two pieces vertically, it looks nicer:

|

|

#4

|

|||

|

|||

|

Ok...I"m stealing this idea..that looks great.

__________________

I'm not a luthier...luthier's know what they are doing.

|

|

#5

|

|||

|

|||

|

That's what I've been doing for the heel as well.

I like your headstock transition! The glue line is at the bottom of the curve? |

|

#6

|

|||

|

|||

|

The last few guitars I built I have the glue line under the fretboard as such:

I've always struggled with this problem and IMO if you are going to have a visible line this way looks best. In this case it looks intentional where as in the traditional sense it looks like something you are trying to hide. Just my thoughts on it from my own perspective. dekutree64's method is very good but more difficult to execute too. |

|

#7

|

|||

|

|||

|

Quote:

I have settled in on a scarf joint at the headstock with a similar-to-Gibson curved V-shape blend from neck to headstock. The scarf joint line, I try to make straight. It works out being a simple volute. Elegant and efficient. And addressing the OP's question about heel block joint lines, I made one neck with a 3 piece laminated heel, and it has become my "demonstrator" neck because I didn't care for the final look. (waste of time, eh!!) It is easy enough to find thick mahogany to make one piece neck blocks. The join line will be visible due to differing grain variations, but there should really be little enough glue that other than differing grain directions, no glue line should be visible. With a well done heel-to-neck carving, this joint should be attractive aesthetically rather than detractive. If your heel-to-neck carving is clumsy, this line will look clumsy as well.

__________________

---- Ned Milburn NSDCC Master Artisan Dartmouth, Nova Scotia |

|

#8

|

|||

|

|||

|

Would love to see that scarf joint, Ned. Any pictures of it on your website?

|

|

#9

|

|||

|

|||

|

Quote:

https://www.facebook.com/ned.milburn...06?pnref=story https://www.facebook.com/ned.milburn...06?pnref=story I think you'll be able to see them. I haven't had time to update my website for some time now.

__________________

---- Ned Milburn NSDCC Master Artisan Dartmouth, Nova Scotia |

|

#10

|

|||

|

|||

|

Quote:

It makes an excellent visual guide for carving the neck too

|

|

#11

|

|||

|

|||

|

Quote:

|

|

#12

|

|||

|

|||

|

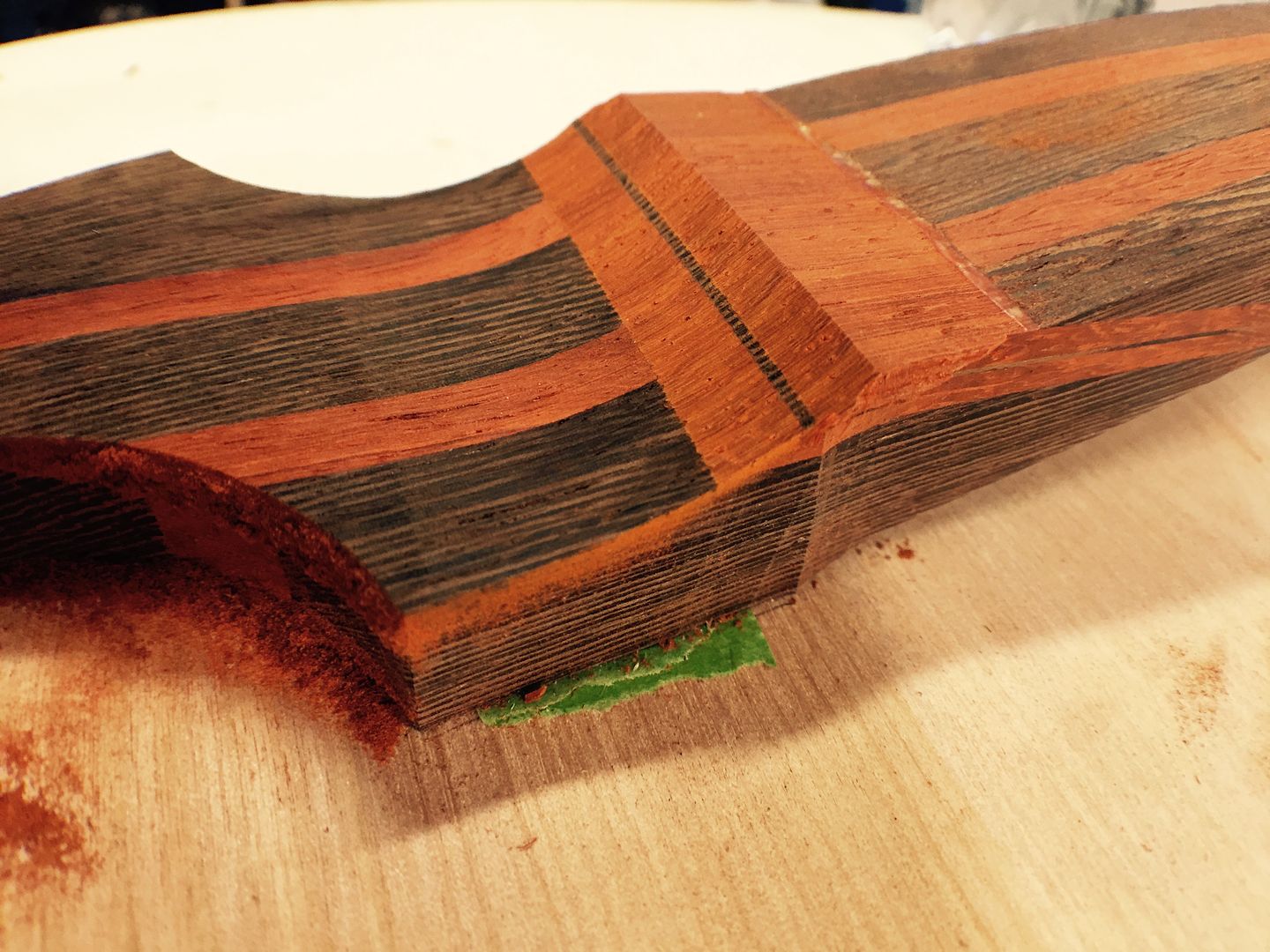

Or you can go with it... accentuate the joint...

|

|

#13

|

|||

|

|||

|

anything is better than the old finger joints on a well known makers guitars.

|

|

#14

|

|||

|

|||

|

Ya gotta love the mother of toilet seat binding too

|

|

#15

|

|||

|

|||

|

yeah, that binding isn't to my taste...

Here's one of my current necks I'm working on. I add some laminations to the scarf joint. Once carved, the volute will have some nice stripes.

|