|

|

#1

|

|||

|

|||

|

I'm trying to sort out the best way to lay out string slots on a new nut for my Yamaha 16-12. I have the Safe-Slot Nut Guard for the depth and it comes with a string spacing ruler, unfortunately these rulers are laid out for 6-string spacing; my question to Stewmac about this yielded a response that wasn't satisfactory, to wit: "Lay it out for 6-string and cut the slots on either side of the marks".

Really? Is this the way it is done by guys who do it all the time/for a living? Kudos if you can do that, but speaking as a reasonably qualified hack, I'd like to know if there is a more accurate process, or a ruler on the market that takes 12-string spacing into account. I've done several 6-string nuts...have it down pretty well, but in this case, I've had a "qualified Luthier" do this 12-string for me twice now and he pooched it both times, so it's down to me. The new bone nut is perfectly fitted to the nut slot...now I just need proper, proportional string spacing at the 1 7/8" nut. Any better/best ideas before I blow my brains out?  Thanks!

__________________

Larrivee L-10 Custom Larrivee DV-10K Larrivee L-03 Taylor 412K ('96) Yamaha LL16-12 (SOLD) PRS 'Studio' (SOLD) Rickenbacker 660-12 (SOLD) Fender USA Deluxe Strat Fender USA Roadhouse Strat Fender MIM/USA Partscaster Fender MIM Nashville Tele Kelsey Custom Hardtail Strat Fender MIM P-Bass |

|

#2

|

|||

|

|||

|

Sorry I can't help you but I'm guessing from experience it's not a simple job.

My Martin Grand J12-40E Special was hard to play when brand new with the factory set up - way too high at the nut. Took it to a shop where they went too far - way too low - they even broke off a bit of the 'tower' between strings 11 and 12. I took it to a different shop to have a new bone nut made from scratch. The guitar tech must have recognized the degree of difficulty and passed the job over to the more experienced store/business founder and I'm glad he did. Superb job. Stick with it, I'm sure you'll get it to work.

__________________

Brucebubs 1972 - Takamine D-70 2014 - Alvarez ABT60 Baritone 2015 - Kittis RBJ-195 Jumbo 2012 - Dan Dubowski#61 2018 - Rickenbacker 4003 Fireglo 2020 - Gibson Custom Shop Historic 1957 SJ-200 2021 - Epiphone 'IBG' Hummingbird |

|

#3

|

|||

|

|||

|

I would think that you'd set your 1st and 12th string marks on the nut, to get properly away from the fretboard edges and then, set up the other string by placing them to either side of the scribed marks on your gauge.

I'd take a calipers and measure the exact spacing between the pairs (on a good nut) to be sure. |

|

#4

|

|||

|

|||

|

Just eyeball it. Make a wood nut or two for practice. Draw lines with a pencil, starting with the two outermost strings, and fill in the rest inbetween. If the spacing looks uneven, erase some lines and try again. Mark fat strings with two lines representing their actual width, rather than a single thin line (assuming you want equal space between strings and not equal center-to-center spacing).

No need for gauges or anything fancy unless you're going to be doing it every day. |

|

#5

|

|||

|

|||

|

First, get the tools you need. The Stew Mac string spacing rule will help you better than eyeballing it or avoiding buying any tool cause you're cheap (buy the tool for the 20$ it costs). And yes, as surprising as it is it really is simple to lay it out, the challenge comes when cutting it properly, go slow and steady.

Just keep in mind that there are no hard and fast rules when it comes to spacing, it's really all about what people want/like. I've made some nuts where the customer bent the low E sting so drastically on a basic G chord that they specifically asked me to move it as close as possible to the low e edge of the fretboard. Even if it's less than perfect it will still be playable provided you don't cut it too low. Don't be too picky. Here's a handy little tutorial on how to use it for 12 string nuts from Stew Mac. Read it and make it happen, I have full confidence you can do a good job with it. (it's down lower on the page) http://www.stewmac.com/How-To/Online...mandolins.html I use the index card trick they describe on that page all the time with great results. Whatever you choose to do, master it and make it happen. Last edited by D. Churchland; 08-19-2016 at 09:49 PM. |

|

#6

|

|||

|

|||

|

You might want to take a look at a thread entitled, "A 12-String Nut for Non-Standard Stringing" at The 12-String Cafe on the Unofficial Martin Guitar Forum, www.umgf.com.

|

|

#7

|

|||

|

|||

|

If you have at least 2 nuts that aren't the way you want (plus the original nut, perhaps?) it would seem that you have more than enough examples of what you don't want, it should be pretty easy to lay out what you do want - it isn't rocket science -

__________________

More than a few Santa Cruz’s, a few Sexauers, a Patterson, a Larrivee, a Cumpiano, and a Klepper!! |

|

#8

|

|||

|

|||

|

I've never used one of those spaced rulers. A friend gave me one but I prefer to do it the way I was taught. It's a little different with a twelve string nut, but it still works out fine.

First, lay out and start the slots for the first and twelfth strings. Next, determine your spacing between the string pairs, and find or make a spacer out of binding material, a popsiclle stick, or whatever. Then use that to set your spacing between the low E strings. Next, with vernier calipers, measure the distance between your primary strings (low E to high E). Then subtract from that number the sum of the diameters of the remaining four primary strings. Divide that number by five, and this is the spacing between your primary strings. Slot all of your pimary strings to the desired depth, and then use your spacer to locate your secondary strings. Cut those to depth, and you're done. |

|

#9

|

|||

|

|||

|

I used to lay the courses out by eye, which was a real pain. Then my friend Paul Woolson showed me his method.

First, lay out the first string location, and then the second string, which in his case is centered 1/16" from he center of the first string. Then lay out the 12th string followed by 11th string, which is centered 3/32" from the center of the 11th string slot. Now, just simply use the Stew Mac to get the spaces of strings 1-3-5-7-9-11, and then strings 2-4-6-8-10-12. I hope that's clear for you. If not PM me and maybe I can clarify it.

__________________

Michael Propsom |

|

#10

|

|||

|

|||

Steve

__________________

Cole Clark Fat Lady Gretsch Electromatic Martin CEO7 Maton Messiah Taylor 814CE |

|

#11

|

|||

|

|||

|

Thanks for the replies. I haven't had a chance to get back into this since I posted; it could very well be that I'm over-thinking this, as I tend to do sometimes.

The problem with the original nut was that it was a POS plastic one...very unfortunate that Yamaha does this on an otherwise stellar guitar (I had to replace the saddle and tuners as well)...but at least it was more or less correctly spaced, although its hard to recall at this point. Unfortunately, the guy I took it to for a new one did not retain the original nut, and then when I took it back to him he made exactly the same mistake on his second try as he did the first, which was to make all the strings the same spacing (!!!???), like a TWELVE string guitar, rather than a guitar with six octave courses. Those old nuts are not going to be any help. I will follow Frank Zappa's credo..."Shut up and play your guitar..." which I like to think applies to stuff like this as well.

__________________

Larrivee L-10 Custom Larrivee DV-10K Larrivee L-03 Taylor 412K ('96) Yamaha LL16-12 (SOLD) PRS 'Studio' (SOLD) Rickenbacker 660-12 (SOLD) Fender USA Deluxe Strat Fender USA Roadhouse Strat Fender MIM/USA Partscaster Fender MIM Nashville Tele Kelsey Custom Hardtail Strat Fender MIM P-Bass |

|

#12

|

|||

|

|||

|

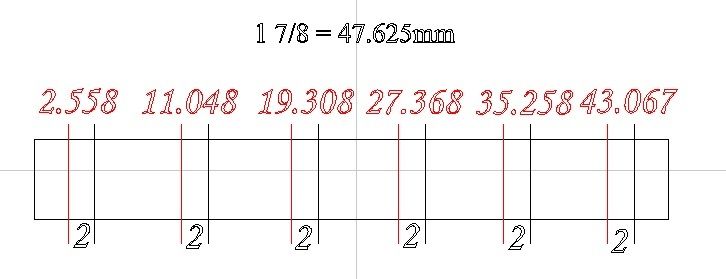

I fired up a drawing program and laid out the spacing bearing in mind the various string size/widths as I went along.

Ideal nut width is 1-15/16", for which I have drawings. If you have the more typical (and cramped) 1-7/8", then you have to shrink to fit.

__________________

-donh- *everything* is a tone control |

|

#13

|

|||

|

|||

|

Quote:

Assuming overall string spacing at 1-11/16" on this slightly wider nut, it would still leave me 1/8" clearance from the outer strings to the edge of the board at the nut...in theory it should be acceptable clearance...is this reasoning sound? I guess I'm going to find out; having limited my previous searches for a pre-slotted bone nut to 1-7/8" I found nothing, however I looked again and found a pre-slotted 1-15/16" nut at Allparts...six bucks (I don't imagine they sell many of these). For six bucks it's worth it to test the theory, anyway and if I find that the spacing is too wide, I will have something of a solid template to work from.

__________________

Larrivee L-10 Custom Larrivee DV-10K Larrivee L-03 Taylor 412K ('96) Yamaha LL16-12 (SOLD) PRS 'Studio' (SOLD) Rickenbacker 660-12 (SOLD) Fender USA Deluxe Strat Fender USA Roadhouse Strat Fender MIM/USA Partscaster Fender MIM Nashville Tele Kelsey Custom Hardtail Strat Fender MIM P-Bass |

|

#14

|

|||

|

|||

|

I really, really think you're completely overthinking this - the layout of the nut is supposed to be pretty even, but you may find that you prefer to have a little more room on the bass side, and have the treble right at the edge - or maybe vice-versa. You may want some of the pairs a bit tighter than others. I generally prefer the treble in a bit from the edge, and the top courses a little tight, as it makes fingering a little easier and lets me wrap my hand around the neck without accidentally muting the high e's - but its all preference. I'd worry a whole lot more about getting all the slots to just the right depth and break angle without going a hair too deep on just one string - ;-)

But seriously - the standard technique to create even spacing is to angle your ruler so the measured width is easily divisible by the number of divisions you want. Metric ruler can really help. Adjust by eye if desired - Quick and easy -

__________________

More than a few Santa Cruz’s, a few Sexauers, a Patterson, a Larrivee, a Cumpiano, and a Klepper!! |

|

#15

|

|||

|

|||

|

Here's my Blueridge 12 string, before and after I cut a new nut for it. I was inspired by a picture of an LKSM-12, on which I noticed the string courses were much closer together than is typical:

A pair of digital calipers, a calculator, and (highly recommended) a pair of 3" round leg dividers will go a long way in helping you get a well-cut nut. (the dividers hold much better than calipers and IMO make the job easier, both in making set marks and in double-checking your work...simply open your calipers to the desired measurement, lay it on the bench, and set your divider legs to the calipers as closely as you can) So let's get down to business. If you're kinda OCD like me, this should help your situation. I found this somewhere else online: Measure the distance between the inside of the E strings. Call this number A. Add the diameter of the 4 inner strings and add them. Call this number B A subracted by B divided by 5 equals the gap between the strings. A reduced formula would look like this: (A - B) / 5 = S (spacing between strings) On bass, this would be (A - B) / 3 = S ...because there are 4 strings, and 3 spaces on the nut between the 4 strings. So you divide by 3 instead of 5. Just for future reference. STEP 1 Set your outside E strings first. On 12 strings I like to set the outside *courses* first, meaning I cut 4 starting slots with a razor saw, for the two low E strings and two high E strings. I do this by eye. It can be a little time consuming. Just go slow, and start with the outermost strings closest to the edge of the fingerboard, then look up some pictures online to decide on your string course spacing. I looked up a picture of an LKSM-12 and decided to have relatively narrow string course spacing. So now you have your 4 outside strings. The courses should be spaced as you want them, and the strings should be the desired distance from the edge of the fingerboard. STEP 2 What you're going to do next is remove the thick low E from the nut, and measure the space from the outside of the octave low E string to the inside of the leftmost high E string. (You can also reverse this process, and measure from the outside of the thick low E string to the inside of the rightmost high E string. That gives you "Number A," and to get "Number B," you measure the corresponding strings. This means LEFTMOST strings if you're starting with the LEFTMOST low E, or the RIGHTMOST strings if you're starting with the RIGHTMOST low E. e.g., "Number B" if you're laying out the LEFMOST course would be the summed up diameter of the octave A, octave D, octave G, and leftmost B string. "Number B" if you're laying out the RIGHTMOST course would be the summed up diameter of the low A, low D, low G, and rightmost B string. This works perfectly because it's custom-tailored to whatever string gauge you're using, which is the basis of cutting a well-spaced nut. And then proceed with the formula. Just remember, on 12 strings, the secret is you want to do one course at a time. Pick one or the other. I've done my best to illustrate how this works in this picture of my 12 string with the nut I cut for it:  Now, once you've done that, and have ONE course of strings laid out, you COULD repeat the process with the other course, but at this point you can simply lay out the string courses by eye. You could even check the spacing between your string courses, and simply use your dividers to get equal spacing between each course. Personally, I put a capo on behind the nut (lightly, I use a G7 capo) to hold the strings relatively firm as I work, so when I relocate them they hold their position. And I use a razor saw to make set marks. I do the ENTIRE nut with a razor saw first, making small set marks just deep enough to hold the strings in place. I leave them shallow enough that if I decide to relocate the slot, I can cut a new one and by the time the slots are fully deepened, I can file the nut from the top down, and the original undesired set marks will be erased, as if they were never there to begin with. Once I'm happy with the layout with the set marks, THEN I break out the nut files. On heavier gauges like a .056, I will usually start with a .016 or .020 nut slotting file on my razor saw mark, because if you start with a .056 right off the bat, the string can wander. Gradually moving up in gauge with the nut slotting files avoids this problem. (that's especially true on bass nuts....try going from a .020" inch set mark to using a .105" nut file.....the string can wander considerably, but if you gradually go to a .042, then .056, then .065, .085, and THEN .105, the string will be in the same spot you made your tiny starting set mark) --------- So in summary, the way I do it is lay out the two outside E string courses first, and carefully by eye. I used a picture of an LKSM-12 nut as reference for mine. Then use the formula to do one course at a time, either the leftmost higher octave, or the rightmost lower octave. You can repeat the process for the second course, or do the second course by eye (with the help of calipers or dividers, preferably), using the first course as a reference. Once you have one string course laid down, it gets a LOT easier. Cutting a nut is hard and takes a lot of repeated practice, but having that formula on hand will go a LONG way in helping you. That being said, there's a reason most people charge 50-60% more money for cutting a 12 string nut, and it's not just because there're more strings. The first couple times I did a 12 string nut I was sweating profusely and felt like I was going cross-eyed after 30 minutes. It does get better with time and practice, trust me  Good luck. Good luck.

|