|

|

#1

|

|||

|

|||

|

Starting at 1:48 it looks like he is using his drill press as some sort of band saw. What's up with that?

http://m.youtube.com/#/watch?v=w_p8jasoeds

__________________

Some Martins Garcia #2 classical Cordoba C10 Luthier Series Tacoma Olympia OB3CE acoustic bass "I don't care what style you want to play. If you want to master good guitar tone, master preparation, attack and release first." ~ Paul Guma |

|

#2

|

|||

|

|||

|

My guess is that he's got a router bit or end mill in there that is following the template. Sort of like an overhead router.

|

|

#3

|

|||

|

|||

|

Your link did not work for me but this may be the technique you are referring to.

__________________

Divots in my fingers Music in my head I wonder what would be If I chose car racing instead. Jim Schofield |

|

#4

|

||||

|

||||

|

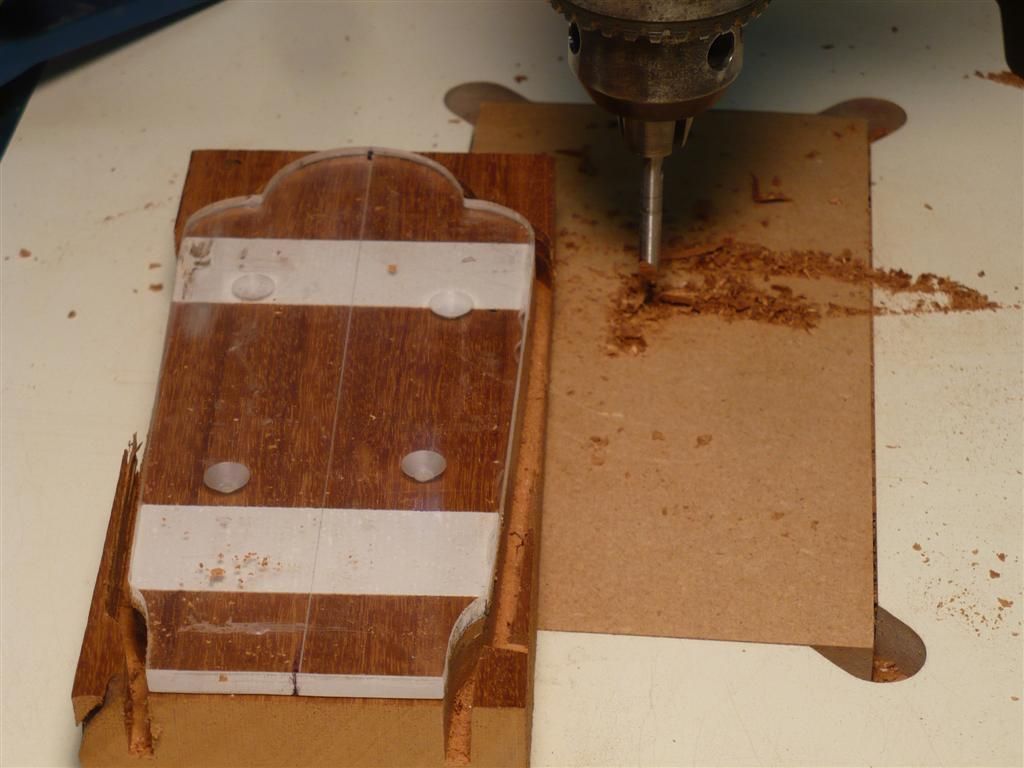

That is Robbie O'Brien's trick for cutting out headstocks with a template. The bit is a 3/16 or 1/4" drill rod or the back end of a one of that size drill bit with a 60* flat honed into the end. What it makes is a cutting tool that works well at slow speeds for following a template. Takes a little while, but once you have a template, you can reproduce a headstock shape in fairly short time with simplicity. Somewhere, probably at LMII in the area where Robbie's You Tubes are, he shows how to make the bit. Here is a picture of my first test using one I made on the butt end of a 3/16 drill. It's tricky to get the drill in the chuck and not get wobble, but it can be done. I keep meaning to get some 3/16 drill stock so I can make one that is easier to chuck-up. The cutting part of the bit is only about 1/4" in length, so the shaft follows a template well.

__________________

Waddy |

|

#5

|

|||

|

|||

|

Here's a fixed version of the OP's link. Advance to 1:48.

|