|

|

#31

|

||||

|

||||

|

Quote:

Quote:

So if true, with this method a guitar may leave the factory with 'the perfect intended' action and saddle height by selecting the bridge that will give this result, but the height of the strings off the soundboard and the weight of the bridge may be 'compromised' (or different than the ideal intended design). Not my idea of how to control things.

__________________

Chuck 2012 Carruth 12-fret 000 in Pernambuco and Adi 2010 Poling Sierra in Cuban Mahogany and Lutz 2015 Posch 13-fret 00 in Indian Rosewood and Adi |

|

#32

|

|||

|

|||

|

Quote:

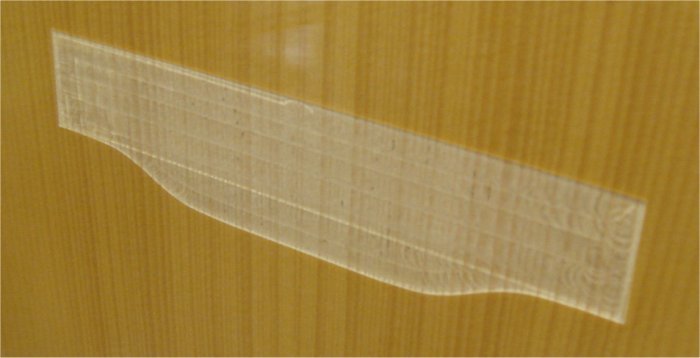

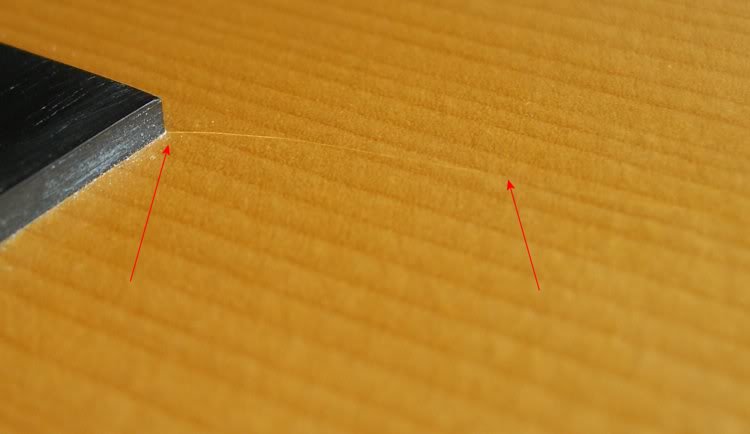

The bridge thickness thing is just a minor example. Bridge fitting is a better example. They used to finish a guitar, mark around the bridge outline and then scrape off the varnish down to wood and then glue on the bridge. That was the old fashioned way of doing it. It worked. But that was a slow operation.  So next, they tacked on a mask to the wood before finishing the guitar. Peel off the mask and the bare wood was there on which to glue on the bridge.  But that created a problem. The edges of the bridge all round (about 1/8") were glued onto the finish (not secure), and due to that being higher than the wood due to the thickness of the finish the glue didn't have a perfect close contact between the bridge and wood. The end result was that people delighted in posting photos on the forums of pieces of paper under the corners and edges of the bridge. So changing the system, chasing the problem, created another problem. That wasn't good. So Martin changed the system of bridge fitting again. To overcome the problem that was caused by overcoming the problem. This time, they CNC routed the nitro finish off the finished top. And then glued on the bridge. Unfortunately that caused another problem. The CNC routing takes off not only the finish, but a small amount of wood too, and therefore the "pocket" was actually deeper than before. Furthermore, the corners of the routing were done with a 1/16" router, which left a tiny radius on the four corners.... onto which the bridge was glued.   That resulted in stress on the lacquer at those points, which on some guitars created small whisker cracks in the finish emanating from the corners of the bridge. Those cracks could take a week to show up, or a couple of months. They were even spotted like that in the stores. But once the cracks started, they grew. Longer and longer. Now, it didn't happen to every guitar. Just some. I happened to have three different new Martins where that problem developed. Lots of other people posted photos of their "whisker cracks". Martin never acknowledged the problem, and it went on for years from 2008.   Typically, people started to "defend" Martin by saying "It never happened to mine", or trotted out the old usual "does it make a difference to the sound" statement. But it was a big deal to those who experienced it in their new guitars. But the point is.... Martin find (or create) a problem, and then chase the problem, which then creates another problem.... and so on. The bridge fitting is just one example. It is the way that they approach things in guitar manufacture. Don't get me wrong, I really love my Martin guitars, and have done since I bought my first one in 1972. There's nothing like the sound of a good Martin. My best and most favourite guitar is a Martin, even though I had to be without it for nine months while it had a neck reset and have the top refinished due to those pesky cracks around the bridge. But contrast this approach of problem chasing with Taylor's approach for example. Bob Taylor realised that in order to mass produce a guitar using CNC methods, that some "traditional" things in guitar construction were going to have to change. So the guitar was re-designed essentially from the bottom up so that it could be produced by CNC methods. Then he designed the CNC in house to do it. The superb neck joint for example. Genius in its simplicity. He wasn't chasing problems. He designed the guitar so that there would not be a problem. So that if a guitar needed a neck reset (as they do sooner or later) then the operation could be done in minutes. Brilliant. Martin have tried to update traditional methods to produce guitars using CNC, but keep tradition. And are therefore chasing their own problems. Rod

__________________

Rod Neep - England |

|

#33

|

|||

|

|||

|

Originally Posted by Todd Yates View Post

"Martin will cover neck resets under warranty to the original owner." I was told by the head of Customer Service and Repair... that Martin made an in-house decision to cover neck resets up to 20 years. There is no such disclosure or disclaimer on the "Lifetime Limited Warranty" only that a decision can be arbitrary. The "Lifetime Warranty" that predated the Limited Lifetime Warranty, was far more oriented toward the customer and did not have the current disclaimers.. and Martin ( nor any other company) can rewrite or re-do or re-interpret an existing warranty. Anyone with a "Lifetime Warranty" cannot be told or excluded from a neck reset at any date. A warranty in effect at time of purchase is part of the "contract" A contract cannot be re written down the road even in the face 9of a "new" "Limited Lifetime Warranty" What Martin is doing on these" out of the box needs neck reset".. is planing the fingerboard and refretting.. and then shaving or replacing the bridges. However that does not correct the two necks on my last two failed custom guitar where the neck was set on the guitar body off by over 5 degrees causing the high e to be 1 1/6th from the board edge and the bass side 1/4. This was the case on a D-18VS (sv) custom and a custom 00-17. The 00-17 was so bad it needed a new top, bridge and neck reset or replacement. Martin said it could not be fixed and told me they destroyed the guitar. Then they had the audacity to tell me after several back to back gross failures " C.F. Martin does not believe we can build a guitar to your satisfaction" You mean, you cannot put a neck on straight ? |

|

#34

|

|||

|

|||

|

I learned 15 years ago, stay away from anything "Martin" built after 1999, but after more thought, changed that to after 1996. My 1962 D 28, bought brand new, had its first, only marginally needed re set this past winter. I truly believe many of the "yo's" on these forums are given a nickel for every "yo" they give. Now we'll hear about this opinion.. Best thing to happen to me, "Bar me from these kiddie forums." Martin 1940D28

|

|

#35

|

|||

|

|||

|

I bought a recently built 000-15M from a forum member that needed a neck reset. I was told by the local (trusted) Martin-certified luthier that he'd seen several such instances with this model.

I acknowledge the statistical uselessness of this anecdote but it left me not wanting a Martin and I sold it at a loss. |

|

#36

|

|||

|

|||

|

one of the prerequisite things i do when i buy any guitar(online or in a shop), is check neckset.

from the getgo(yep, i carry a 24" steel ruler in the vehicle when i go guitar shopping-just in case the shop "doesn't have one handy". likewise i have a picture taken and sent if i'm buying used-if someone doesn't want to do it or doesn't have the time, i pass on the purchase. to me its no different than showing a picture of the top/back and headstock.

|

|

#37

|

|||

|

|||

|

Check every guitar you buy with a straight edge and return any that are wrong. It is your responsibility to the guitar playing community to make the mfg do things right. If you just ignore it they wont change. Remember Martin is a business first and most important. They are not interested in making good guitars.

|

|

#38

|

|||

|

|||

|

I've owned about 10 Martins. None of which had any structural problems.

I have seen one in a shop that had neck angle issues however.

__________________

"I used to try to play fast, and it’s fun for a minute, but I always liked saxophone players. They speak on their instrument, and I always wanted to do that on the guitar, to communicate emotionally. When you write, you wouldn’t just throw words into a bowl. There has to be a beginning, middle and end. Same thing with phrasing on the guitar" Jimmie Vaughan |

|

#39

|

|||

|

|||

|

just threw my d15,00028ec, and d-18 in the trash. this thread makes me sad

|

|

#40

|

|||

|

|||

|

Can I drive over and take out yer trash? ..lol

|

|

#41

|

|||

|

|||

|

yes but get ready to wipe off all the tears because apparently Martins are prone to problems.

I had no issues with my guitars until I read the internet. |

|

#42

|

|||

|

|||

|

I've had four Martins purchased new - a 1985 D-28, a 1990 J-40 made in the custom shop, a 1993 OOO-16, and finally the weird aluminum topped resonator model that they made briefly a few years ago. Two of the four needed neck resets, one within the first year (resonator) and the custom shop high-end model after about eight years. So I'm batting .500 on Martins, and only one of the four remains with me today. i never sold one with known problems, making Martin do the neck reset under warranty first.

OTOH none of my seven Taylor guitars have needed neck angle changes (all NT necks) or even action adjustments. So I'm batting 1000 on Taylor's. Ditto for Seagull and Rainsong (two each). Guess which brand I no longer buy?? |

|

#43

|

|||

|

|||

|

I bought a D-18 a couple years ago from a large internet dealer that gets lots of kudos on forums just like this one. Great price, quickly shipped, etc.... Didn't play well. Took it to a local service center and he confirmed the geometry was not "ideal", but could get it "pretty good" by playing with the bride and saddle. I said no thanks, and returned it (hassle free) to the dealer for a full refund. I later found a much older, worn it, used D-18 at a guitar show that I now own and love.

These problems happen. Lots of guitars built, bound to be some issues. Still a great company, but I see this situation a lot with new Martins hanging in stores. Back then, I didn't really know what to look for...

__________________

Taylors, Martins, Composite Acoustic, and an Alvarez. |

|

#44

|

|||

|

|||

|

Quote:

I will buy another Martin sometime but it will either be used/old or a bolt on. Most likely a bolt on as old Martins don't have truss rods.

__________________

Science doesn't care what you believe. Doerr/Taylor Last edited by sbeirnes; 10-07-2014 at 09:09 PM. |

|

#45

|

|||

|

|||

|

Huh?? Their business is dependent on them turning out a quality product. I can't even believe I just read that statement.

|