8. A CNC machine is hacking away at the necks for pre-shaping, before Jean works on them.

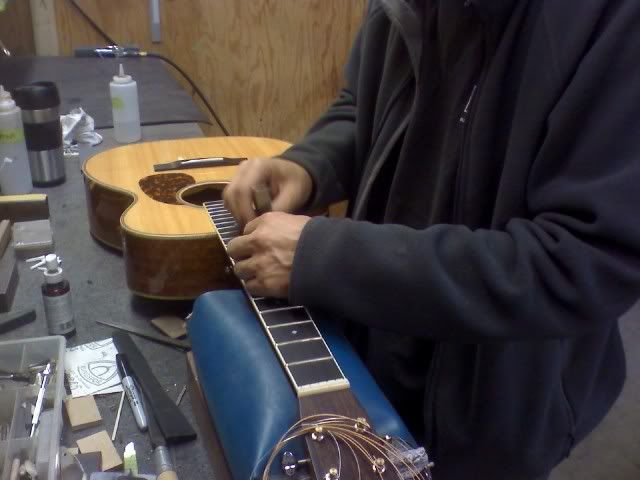

9. This is actually my guitar (OM-50) being worked on to correct the uneven frets, the reason why I stopped by the factory in the first place. Unfortunately, it turned out to be something that couldn't be corrected within an hour. So I left it in the factory to have them work on it for a little longer before shipping it back to me early next week.

10. This is one of many buffing machines. One of the reasons you see some empty stations is that I came fairly early in the morning (around 9 AM). Another reason is that Larrivee is actually scaling down the production a bit. Right now they're putting out an average of 10 acoustics a day at Oxnard and 30 at Vancouver.

11. These are solid-body electric bodies.

12. The bodies and the necks are being prepared before the spraying of the finish in the paint room.

13. Holes for the bridge pins are being drilled in.

14. There's a lot of money in this storage room. And the smell of the UV finish was quite overwhelming.