Here's Dan's latest update:

So, it's been a couple of weeks.

I sanded the outside of the deep bowl mold so the fiberglass splinters don't cut up my hands while handling it and trimmed the flange.

Now, this is ready to mold deep bowls. I've got some 8.5-oz 2x2 twill cloth on order, so I will probably mold a test bowl in the next couple of weeks or so.

I would have been done with the parlor bowl mold a few days ago, but I ran into a problem of my own making. Read on.

Since I'd planned to mold the parlor bowl and flange in two steps instead of one, I prepped the bowl and parting plate by waxing them and applying a fresh layer of PVA.

I mounted the bowl so it was about an inch off the parting plate, cut the cloth pieces I needed, mixed up the epoxy and laid up the bowl. Under normal circumstances the epoxy will start to gel, or what's known as the green state in a few hours. It's not gooey or tacky, but not yet fully cured. It's at this stage that it's easiest to trim.

After a few hours, the epoxy was still gooey. Given how slowly it was curing, I figured it would be a few more hours before it was green, so I turned on the heat lamps, then went to bed. When I got up in the morning, I checked it and it wasn't as gooey, but it was still was very soft and still very tacky. So, I carefully trimmed the edge of the bowl and left it under the heat lamps until I got home from work.

When I got home, I checked it and it was still very tacky. Weird. Since it hadn't been quite the full 24 hours for the epoxy to reach full cure, I left it for a couple more hours. I checked it again and still very tacky.

Hmmm... Normally, epoxy only acts like this when it's either very old, or not mixed properly. I knew I'd measured it carefully, so I checked the label on the can of hardener, which tells the proportion of mixing.

Whoopsie! I found the problem. The surface coat is mixed by weight to a ratio of 100:11. The epoxy is mixed by weight to a ratio of 100:27. I'd mixed the epoxy using the surface coat ratio, which means that I'd only put in less than half the amount of hardener than what was needed. No wonder it never cured.

Luckily, I'd put a layer of PVA on the bowl before I started, so I was able to carefully roll the epoxy and glass off the bowl leaving it pretty clean. I also cleaned the uncured epoxy off the parting plate using denatured alcohol.

Time to start over. I waxed the bowl and the parting plate and sprayed a fresh coat of PVA. (again) I cut new pieces of cloth while I waited for the PVA to dry. This time I carefully mixed up a new batch of epoxy using the correct ratio and started the lay-up again.

The 1-3/4 oz. and 5-oz cloth is on.

I added a strip of 17-oz tooling cloth to reinforce the center of the bowl, then another layer of 5-oz cloth on top of that.

I let this cure until it was green, then trimmed the lay-up so it was flush with the top of the bowl and let it cure for 24 hours.

Once it was cured, I separated the bowl from parting plate and fully sanded the outside while it was still on the plug so it was ready for building up the flange.

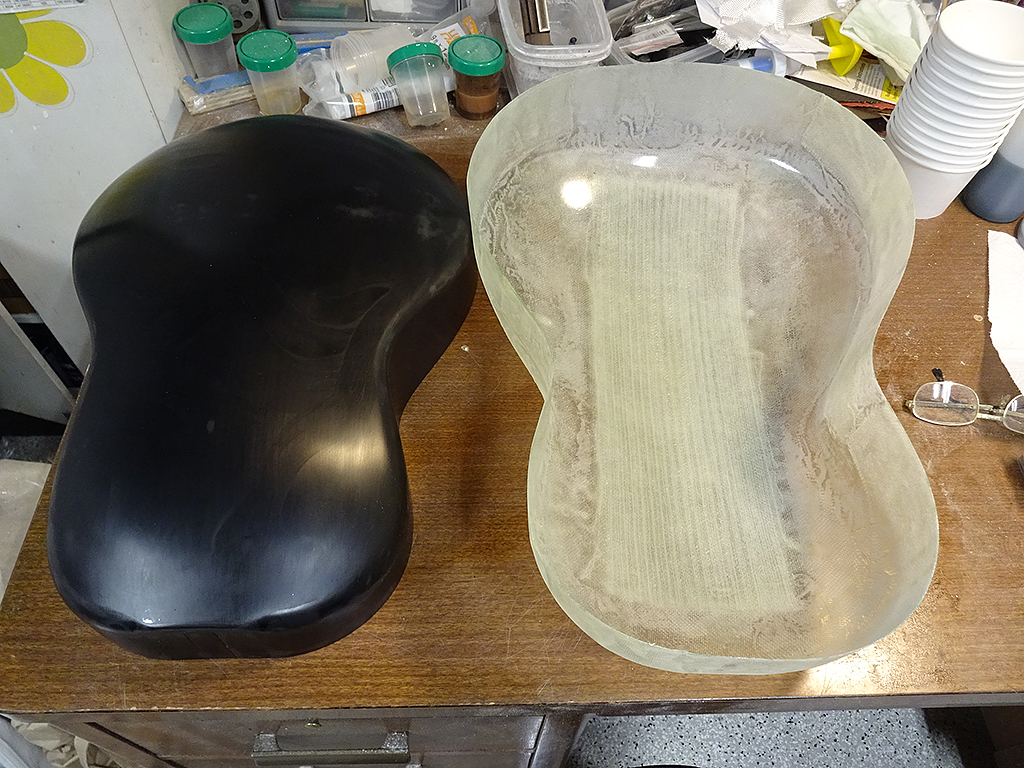

The bowl is separated from the plug and both are in good condition.

I cleaned up the parting plate, waxed it and added a fresh layer of PVA. I set the bowl onto the parting plate, then put a couple of small sand baggies on it to keep it from moving while I built up the flange.

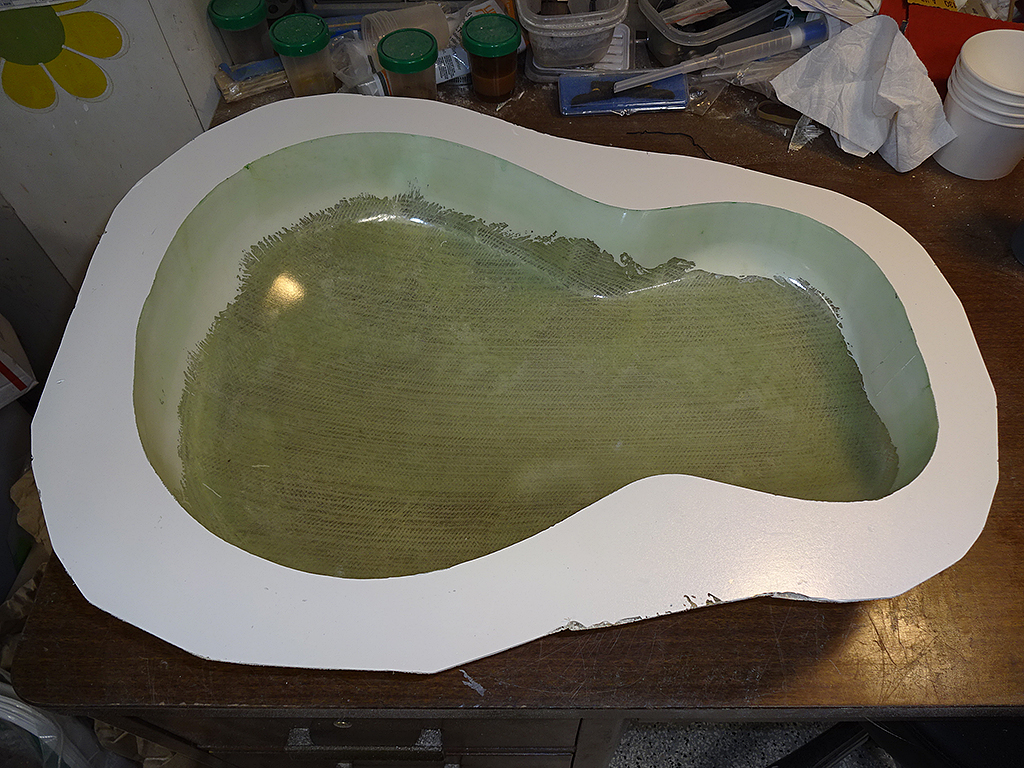

Surface coat has been added to make the flange and to build up the fillet area between the bowl and flange.

Once the surface coat had kicked over to the green state, I removed the sand baggies and added tooling cloth to the sides and flange, then a final layer of tooling cloth to the bottom of the bowl. I turned on the heat lamps and left it to cure overnight.

Success! I removed the mold from the parting plate, trimmed the flange, sanded the outside so I don't cut up my hands and trimmed the flange.

I washed off the PVA and it is now ready to mold parlor bowls.

Phew! Finally I can get back to the process of building Patch's guitar.

The only thing left on these molds is to glue on a couple of legs to the upper bout area of the flanges so they sit level.

I'll do that when I get ready to lay up the test bowls in a couple of weeks. Right now, I'd rather step away from the molding process and build Patch's guitar.

__________________

Well, it looks like one of those desiderata days.....

MY OVATIONS

Spruce: Patriot #76, 1768-7LTD, 1122, 6774, 1779 USA, 1657-Adi

Redwood: 2001-X, 1537-X, 1713-X, FD14-X, Dan Savage 5743-X

Koa: 2078LXF, 1768-X, 1997-X

12-string: 1755, 1615-X Walnut

Exotic tops: 1768-XWF (Bubinga), 1987-M (Mahogany), Adamas 1681-X (Q. Maple)

Others: MM-68-7LTD Mandolin, MM-868-X Mandocello

|